Kaca Borosilikat CORNING PYREX SG3.3

CORNING PYREX SG3.3 is a high borosilicate glass with extremely high chemical stability and excellent thermal expansion properties, especially suitable for use in high temperature and strong corrosive environments. SG3.3 glass gets its name from its excellent low coefficient of thermal expansion (approximately 3.3×10⁻⁶/K), which enables it to maintain a stable form under conditions of large temperature changes and avoid damage caused by thermal stress. In addition to its powerful physical properties, PYREX SG3.3 is highly transparent and is an important part of laboratory equipment, chemical containers and various precision instruments.

-

Excellent thermal stability:PYREX SG3.3 has a thermal expansion coefficient of 3.3 × 10⁻⁶/℃, which makes it excellent in high and low temperature environments and can effectively resist thermal shock.

-

Excellent chemical tolerance:The glass has good resistance to a variety of chemicals and can resist the attack of acids, bases and organic solvents, making it suitable for use in laboratory and industrial applications.

-

High light transmittance:PYREX SG3.3 has a light transmittance of over 90% in the 400-800 nm range, ensuring clear visual effects in optical applications.

-

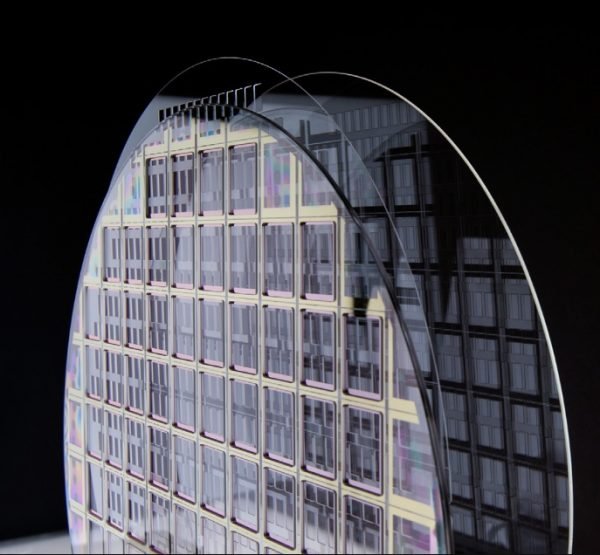

Compatibility with silicon materials:The thermal expansion coefficient of the glass matches that of silicon material, making it ideal for cover glass in the semiconductor industry, enabling stress-free, bubble-free welding.

-

Consistent surface quality:PYREX SG3.3 provides a consistent, direct-bonding surface that eliminates the need to distinguish between front and back, simplifying the manufacturing process and increasing productivity.

CORNING PYREX SG3.3 is a borosilicate glass with a thermal expansion coefficient that matches that of silicon, effectively combines with silicon during anodic bonding, and has a thermal expansion rate that can withstand high temperatures and harsh environments. More importantly, since the CORNING PYREX SG3.3 contains an alkaline component, an efficient anodic bonding process can be achieved. When the temperature continues to rise up to 450 ℃,CORNING PYREX SG3.3 can still provide a consistent, bondable surface, do not need to distinguish between one side and the other side, through the use of industry standard bonding equipment, can be carried out without voids, low stress bonding, and ultimately produce strong and durable bonds, without the need for adhesives or excessive temperatures.

This product is specially designed for anodic bonding applications in the semiconductor and electronics industries and can withstand high temperatures and harsh environments. CORNING® PYREX® SG3.3 provides a consistent, bondable surface that eliminates the need to distinguish between front and back sides for void-free, low-stress bonding using industry-standard bonding equipment.

Sesuaikan Kebutuhan Kaca Optik Anda atau Tanyakan Tentang Solusi yang Disesuaikan

Selama proses pembayaran di situs web kami, Anda dapat memilih layanan pemotongan dan penandaan laser khusus untuk kaca optik Anda.

Jika kebutuhan Anda lebih kompleks, kami menyarankan Anda untuk menghubungi teknisi penjualan kami melalui formulir ini untuk mendiskusikan kebutuhan Anda secara mendetail. Selama percakapan, kami akan fokus pada pertanyaan-pertanyaan kunci berikut:

- Dapatkah kami membantu Anda mencapai tujuan desain dengan cara yang lebih hemat biaya?

- Akankah solusi Anda berkinerja optimal di lingkungan aplikasi?

- Bagaimana kami dapat memanfaatkan keahlian teknis kami untuk menyempurnakan desain dan produk Anda?

- Apakah desain ini cocok untuk produksi dan produksi massal?

Sebagai penyedia profesional di bidang kaca optik, kami menawarkan layanan desain dan manufaktur khusus untuk para insinyur dan tim teknis, memastikan setiap proyek memenuhi standar kinerja dan kualitas yang ketat.

Izinkan kami menerapkan pengalaman dan keahlian kami pada proyek baru atau yang sudah ada untuk membantu Anda mencapai hasil terbaik.