CORNING PYREX SG3.3 Borosilicate Glass

CORNING PYREX SG3.3 is a high borosilicate glass with extremely high chemical stability and excellent thermal expansion properties, especially suitable for use in high temperature and strong corrosive environments. SG3.3 glass gets its name from its excellent low coefficient of thermal expansion (approximately 3.3×10⁻⁶/K), which enables it to maintain a stable form under conditions of large temperature changes and avoid damage caused by thermal stress. In addition to its powerful physical properties, PYREX SG3.3 is highly transparent and is an important part of laboratory equipment, chemical containers and various precision instruments.

-

Excellent thermal stability:PYREX SG3.3 has a thermal expansion coefficient of 3.3 × 10⁻⁶/℃, which makes it excellent in high and low temperature environments and can effectively resist thermal shock.

-

Excellent chemical tolerance:The glass has good resistance to a variety of chemicals and can resist the attack of acids, bases and organic solvents, making it suitable for use in laboratory and industrial applications.

-

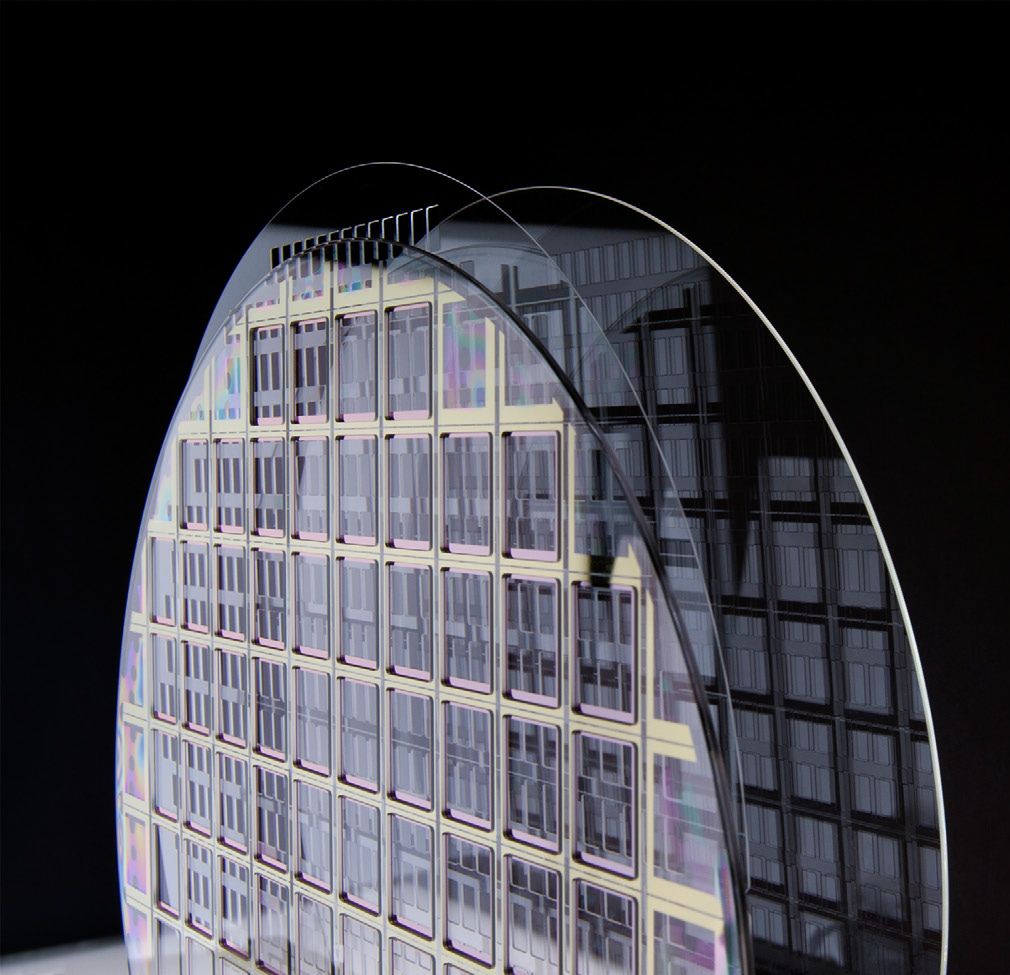

High light transmittance:PYREX SG3.3 has a light transmittance of over 90% in the 400-800 nm range, ensuring clear visual effects in optical applications.

-

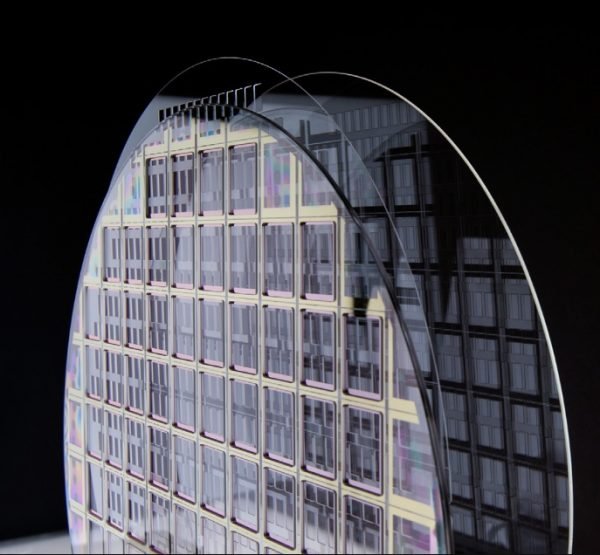

Compatibility with silicon materials:The thermal expansion coefficient of the glass matches that of silicon material, making it ideal for cover glass in the semiconductor industry, enabling stress-free, bubble-free welding.

-

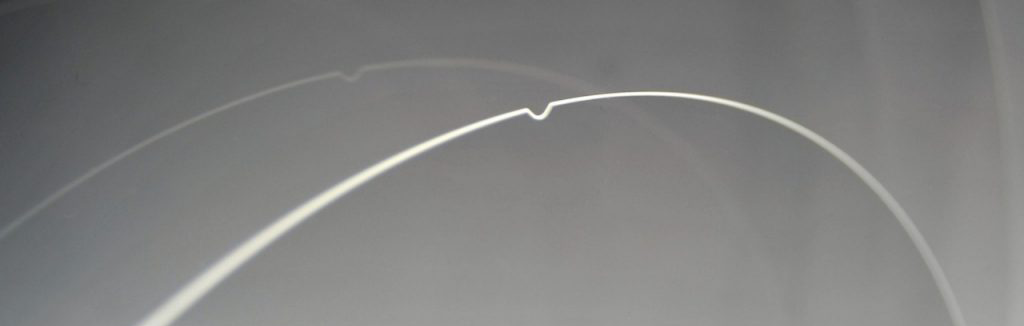

Consistent surface quality:PYREX SG3.3 provides a consistent, direct-bonding surface that eliminates the need to distinguish between front and back, simplifying the manufacturing process and increasing productivity.

What Is Corning Pyrex SG3.3 Borosilicate Glass?

CORNING PYREX SG3.3 is a borosilicate glass with a thermal expansion coefficient that matches that of silicon, effectively combines with silicon during anodic bonding, and has a thermal expansion rate that can withstand high temperatures and harsh environments. More importantly, since the CORNING PYREX SG3.3 contains an alkaline component, an efficient anodic bonding process can be achieved. When the temperature continues to rise up to 450 ℃,CORNING PYREX SG3.3 can still provide a consistent, bondable surface, do not need to distinguish between one side and the other side, through the use of industry standard bonding equipment, can be carried out without voids, low stress bonding, and ultimately produce strong and durable bonds, without the need for adhesives or excessive temperatures.

This product is specially designed for anodic bonding applications in the semiconductor and electronics industries and can withstand high temperatures and harsh environments. CORNING® PYREX® SG3.3 provides a consistent, bondable surface that eliminates the need to distinguish between front and back sides for void-free, low-stress bonding using industry-standard bonding equipment.

Key Properties of Corning Pyrex SG3.3 Glass

- Low Thermal Expansion: Coefficient of thermal expansion 3.3 × 10⁻⁶/K for excellent thermal shock resistance

- Superior Chemical Durability: Outstanding resistance to acids, alkalis, and organic solvents

- High Temperature Resistance: Continuous operating temperature up to 500°C

- Excellent Optical Clarity: High transmission across visible and UV spectrum

- Mechanical Strength: Enhanced resistance to thermal and mechanical stress

- Dimensional Stability: Maintains precise tolerances under temperature variations

Custom Corning Pyrex SG3.3 Glass Manufacturer In China

As a leading Corning Pyrex SG3.3 Borosilicate Glass manufacturer in China, we specialize in precision processing and custom fabrication of Corning Pyrex SG3.3 substrates for diverse industrial applications. Our state-of-the-art facilities and experienced engineering team deliver tailored custom optical glass solutions with guaranteed quality and competitive pricing for global customers.

We proudly support universities, laboratories, and research institutes worldwide, providing not only high-performance Corning Pyrex SG3.3 Borosilicate Glass but also technical guidance and collaborative customization to accelerate innovation in scientific research, pharmaceutical manufacturing, and industrial processing.

Get a Quote for Corning Pyrex SG3.3 Processing

Corning Pyrex SG3.3 Glass Typical Applications including:

- Corning Pyrex SG3.3 Borosilicate Glass wafer

- Corning Pyrex SG3.3 Glass substrate

- Corning Pyrex SG3.3 Glass plate

- Corning Pyrex SG3.3 Glass tube Microfluidic glass chip

Materials and Specifications We Offer

| Property | Specification | Typical Applications |

|---|---|---|

| Thickness Range | 0.5 mm – 50 mm | Laboratory equipment, optical components |

| Size Capability | Up to 1200 mm × 800 mm | Large format windows, industrial equipment |

| Surface Quality | <1 nm Ra (optical polish) | Precision optics, laser applications |

| Flatness | <2 μm over 100 mm | Semiconductor wafers, optical substrates |

| Edge Quality | Ground, polished, or fire-polished | Custom requirements |

| Thermal Expansion | 3.3 × 10⁻⁶/K | High-temperature applications |

Custom dimensions available per customer drawings and specifications. Prototype to high-volume production capabilities.

Corning China Agent – Your Trusted Partner in China

As an authorized Corning China Agent (China distributor), we provide:

Direct Factory Pricing & Fast Delivery

Technical Support & Application Engineering

Custom Processing & Value-Added Services

Quality Assurance & ISO 9001:2015 Certification

Flexible MOQ from Prototypes to Mass Production

Export Documentation & Global Shipping

Why Choose Our Corning Pyrex SG3.3 Borosilicate Glass Services?

Advanced Manufacturing Capabilities Our precision processing equipment and temperature-controlled facilities ensure consistent quality for Corning Pyrex SG3.3 Borosilicate Glass wafer and substrate applications.

Technical Expertise Experienced glass engineers provide design optimization and process consulting for your specific thermal and chemical requirements.

Quality Assurance Comprehensive inspection and testing protocols guarantee dimensional accuracy, thermal performance, and chemical resistance.

Global Supply Chain Efficient logistics and export capabilities serve customers worldwide with competitive lead times.

Competitive Pricing Advantage We offer factory-direct pricing, allowing us to deliver cost-effective solutions without compromising on quality — ideal for both research-scale prototyping and industrial mass production.

Frequently Asked Questions (FAQ)

Q: What makes Corning Pyrex SG3.3 Borosilicate Glass different from regular glass?

A: Corning Pyrex SG3.3 Borosilicate Glass features low thermal expansion (3.3 × 10⁻⁶/K), superior chemical resistance, and high-temperature stability up to 500°C, making it ideal for demanding scientific and industrial applications where regular glass would fail.

Q: Can you process Corning Pyrex SG3.3 Borosilicate Glass wafers for semiconductor applications?

A: Yes, we offer complete Corning Pyrex SG3.3 Borosilicate Glass wafer processing including precision cutting, surface polishing, anodic bonding preparation, and specialized cleaning for semiconductor and MEMS applications.

Q: What is the minimum order quantity for custom Corning Pyrex SG3.3 processing?

A: We support both prototyping (as low as 1 piece) and high-volume production. MOQ depends on specific processing requirements and can be discussed based on your project needs.

Q: What quality certifications do you maintain for Corning Pyrex SG3.3 processing?

A: We maintain ISO 9001:2015 certification and follow strict quality control protocols including dimensional inspection, thermal stress analysis, chemical resistance testing, and surface quality verification for all processed substrates.

Q: Do you provide technical support for application-specific requirements?

A: Yes, our technical team provides comprehensive support including material selection guidance, thermal analysis, chemical compatibility assessment, and custom design consultation for your specific application needs.

Q: Can Corning Pyrex SG3.3 Borosilicate Glass be used for microfluidic applications?

A: Definitely. Corning Pyrex SG3.3 Borosilicate Glass is excellent for microfluidic devices due to its chemical inertness, optical clarity, and compatibility with anodic bonding processes commonly used in microfluidic chip fabrication.

Q: Is there a channel to purchase Corning Pyrex SG3.3?

Corning has authorized Guangzhou Lighting Glass Co., Ltd. as the designated distributor in China. You can obtain genuine materials through them or directly cooperate with us.

Contact us today for your Corning Pyrex SG3.3 Borosilicate Glass processing needs – from prototype to production, we deliver precision and quality you can trust.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.