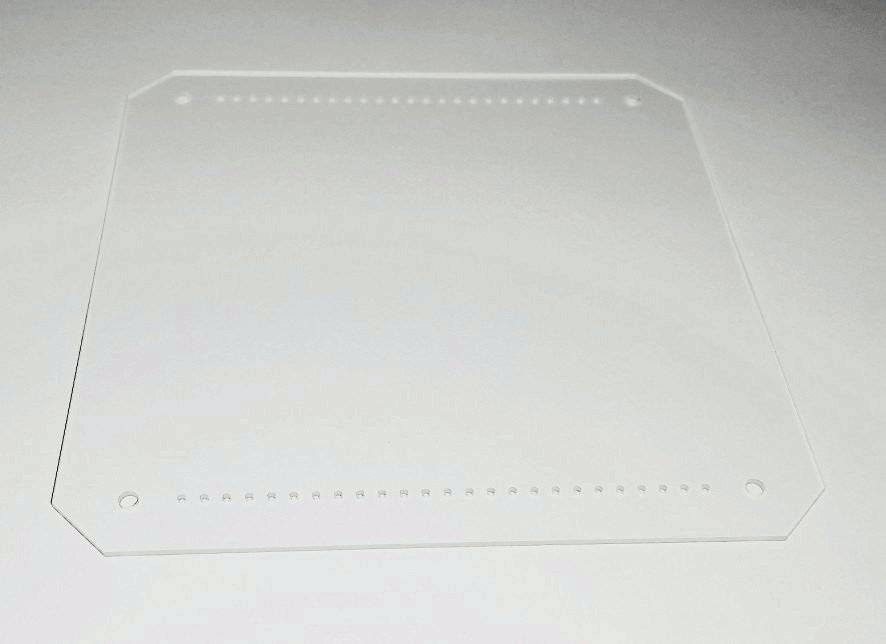

CNC Glass Machining refers to the use of Computer Numerical Control (CNC) technology to precisely shape, cut, and finish glass materials. CNC machining utilizes computerized control of machine tools to perform various tasks, such as lightweighting, drilling, coring, edging, beveling, 3D contouring, and more, with high accuracy and repeatability. In the case of glass, CNC machining is used to create complex shapes, intricate features, and tight tolerances in glass substrates.

We Key Advantages of Our CNC Glass Machining Services:

1.Unmatched Precision and Accuracy Our CNC glass machining services provide industry-leading precision, capable of achieving micron-level tolerances. Whether producing high-precision lenses, prisms, wafers, or other optical components, we can machine to exact specifications, meeting the strictest requirements.

2.Processing a Wide Range of Glass Materials We can handle various types of glass, including:

- Borosilicate Glass

- Soda-Lime Glass

- Quartz Glass

- Fused Silica

- Glass Ceramics

- Optical Glass

- Ultra-thin Glass

These materials are widely used across industries such as optics, electronics, telecommunications,bioscience and medical devices. Our advanced machining equipment and experienced operators ensure that every batch of glass meets the highest processing standards.

3.Comprehensive Machining Capabilities Our CNC equipment can perform a variety of machining tasks, including:

- Boring

- Drilling

- Engraving

- Grooving

- Pocketing

- Slotting

- Surfacing

Whether your project involves precision machining of optical components or industrial glass parts requiring strength, we can provide high-quality solutions.

4.Premium Tools for Exceptional Results To address the challenges of glass machining, we use diamond tools for cutting and grinding, ensuring excellent processing results that can handle the hardness and brittleness of glass. Additionally, our multi-axis CNC equipment allows us to perform complex, multi-dimensional cuts and feature machining, offering high flexibility and customization to meet your specific needs.

5.Applications of Our CNC Glass Machining:

- Optics: Optical lenses, prisms, fibers, light guides, etc.

- Electronics: Touch screens, displays, sensors, etc.

- Medical: Laboratory glassware, optical sensors, medical imaging equipment, etc.

- Aerospace: Lightweight glass components for spacecraft, satellites, etc.

- Semiconductors: Glass substrates for semiconductor manufacturing.

Why Choose Us for CNC Glass Machining?

- High Precision and Repeatability

Our CNC technology ensures each part meets the highest standards, with minimal deviation between parts, ensuring product consistency and superior quality. - Customization Capabilities

Whether it’s custom shapes, sizes, or specific functional requirements, our CNC machining capabilities can meet even the most complex design demands, providing tailor-made solutions. - Efficiency and Fast Turnaround

Automated CNC machining improves production efficiency and reduces manual labor. Whether small or large production runs, we can deliver projects on time with efficient processes, ensuring deadlines are met. - High-Quality Service and Expertise

With a commitment to top-notch customer service, our deep industry knowledge and extensive experience enable us to provide precise, reliable CNC glass machining solutions. - Strict Quality Management System

We adhere to an ISO 9001:2015 certified quality management system, ensuring that every project meets the highest quality standards. ensuring our services meet security and compliance industry requirements.

Ready to Start Your Project?

If you need precision glass machining services, our team is here to assist you. Whether for prototype development, small batch production, or large-scale manufacturing, we can complete your project on time with high-quality results. Contact us now to learn how our CNC glass machining services can meet and exceed your expectations.