At LIGHING GLASS, we offer a comprehensive range of glass edge processing services to meet the needs of various industries, including optics, electronics, medical devices, aerospace, and more. Our advanced CNC technology and expert team enable us to deliver high-precision glass edges, ensuring that every project, whether a prototype or large-scale production, meets the highest precision standards. We provide customized solutions for both simple and complex glass edge profiles, ensuring a perfect edge for each application.

Our CNC Glass Edge Processing Capabilities:

We use state-of-the-art CNC equipment to create a variety of edge contours, from simple straight edges to complex custom contours. We apply a variety of edge types, including 45° angles, rounded corners, radius blends and custom designs. Whether your project requires sharp, clean edges or rounded corners , we can meet your precise specifications

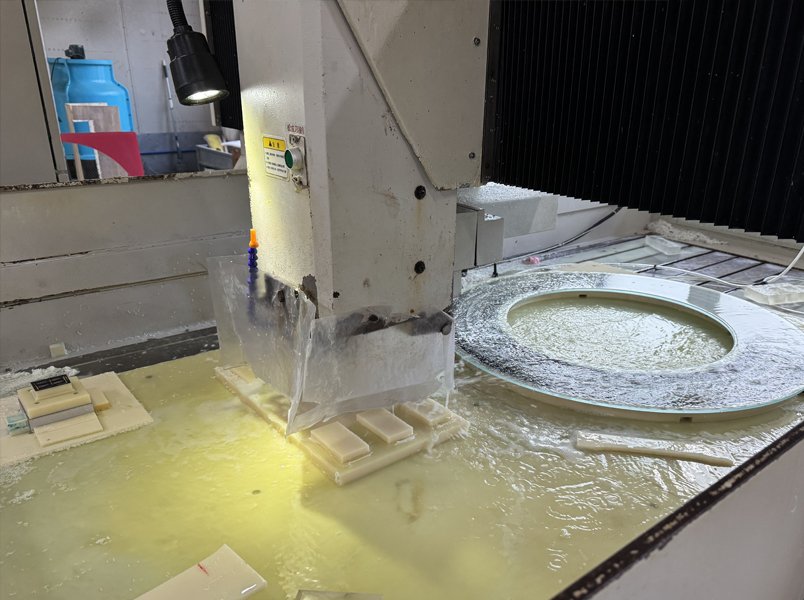

CNC glass edging: Our precision CNC edging stations provide flexible machining for a variety of edge profiles. We can design and produce almost any edge shape, including semi-standard planes, notches, alignment marks, cavities and holes. The process ensures precise edge geometry and tight tolerances, typically within ±0.20mm. We use multiple tool changes in a single program to effectively and accurately apply these features.

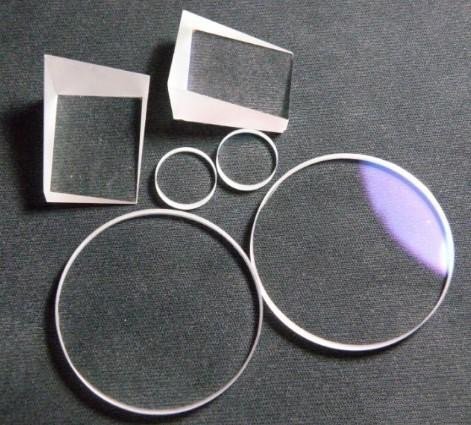

Edge profiles: Our CNC system can create a variety of edge profiles, such as:

- 45° Edge Cut: Ideal for certain optical and structural applications, these cuts provide clean, sharp edges with extreme precision.

- Rounded Edges: Rounded corners help eliminate sharp points, reducing the risk of breakage and chipping. We can achieve any required radius with precision, providing the best durability.

- Custom Profiles: If your project requires a unique edge profile, we can design and manufacture custom shapes, including corner radii, notches, and even window or cavity cuts.

Additional CNC Features: Our CNC systems also allow us to integrate features such as notches, flats, holes, and other precision elements directly into the edge profile. Whether for functional components in electronics or fine processing in optics, our CNC processes provide the necessary precision to meet the strictest tolerance requirements. Other Glass Edge Processing Methods: In addition to CNC edge processing, we also offer other glass edge processing methods to meet the needs of different projects, providing multiple options to accommodate various thicknesses and tolerance requirements.

- Hand Edging: For smaller parts or projects with less stringent requirements, our hand edging method provides an efficient and cost-effective solution. The grinding wheel operation allows our technicians to handle glass edges according to specified dimensions, ensuring clean and smooth non-critical edges.

- Mechanical Scribing: Our mechanical scribing process is used to precisely initiate glass cutting, particularly for thin glass applications. This method ensures flawless edge conditions, which are crucial for the strength and flexibility of the glass. From ultra-thin 100µm glass to glass up to 10mm thick, our scribing process is optimized for blade type, angle, pressure, depth, and speed, creating perfect edges before further processing, whether CNC grinding, hand seaming, or other edge treatments.

Why Choose Us for Glass Edge Processing?

- Precision & Flexibility: Our CNC systems allow us to process a wide range of edge profiles, thicknesses, and custom designs, ensuring your glass components meet your exact requirements.

- Quick Turnaround: With advanced equipment and efficient processes, we can deliver high-quality glass edges quickly, ensuring timely project completion.

- Cost-Effective Solutions: We offer cost-effective edge processing solutions for both small batch production and mass manufacturing. Whether you need high-end precision processing or economical hand edging, we can tailor our services to fit your budget and volume.

- Custom Solutions: Our team excels at designing custom edge profiles for unique applications. We can help you select the best edge type to ensure both functionality and durability.

- ISO 9001 Certification: As an ISO-certified company, we adhere to strict quality control standards, ensuring that every project delivers consistent, reliable results.

Industries Served:

Our CNC glass edge processing services are ideal for a wide range of applications, including:

- Optical Components: Lenses, prisms, and other optical components that require precise edge geometry.

- Medical Devices: Glass components for diagnostic equipment, laboratory tools, and medical imaging devices, where edge integrity is crucial.

- Aerospace & Electronics: Glass parts for aerospace and electronics applications that demand high-precision edges and durability.

- Display Glass: Glass components for smartphones, televisions, touchscreens, automotive displays, and other devices, where edge precision and strength are essential.

Start your project

Start Your Glass Edge Processing Project At LIGHING GLASS, we are committed to delivering high-precision, reliable, and cost-effective glass edge processing solutions. Whether your project requires CNC machining, hand edging, or mechanical scribing, our team has the expertise to deliver perfect edges for your application. Contact us today to learn more about our services or request a quote for your next project. We look forward to working with you to create high-quality glass components with precision and efficiency.