JGS Quartz Glass

JGS quartz glass is a high-purity silica glass known for its exceptional optical clarity, thermal stability, and chemical resistance. Available in grades JGS1, JGS2, and JGS3, it is widely used in applications such as photolithography, laser optics, and infrared devices. With excellent UV transmission and the ability to withstand high temperatures, JGS quartz glass is ideal for demanding environments in industries like telecommunications, semiconductor manufacturing, and scientific research. Its unique properties make it a preferred choice for high-performance optical components.

-

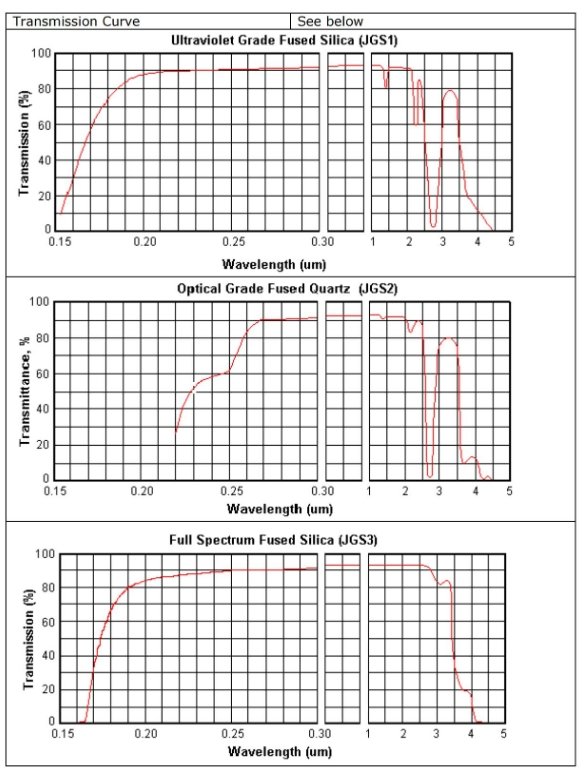

Excellent UV transmittance: UV transmittance of over 90% at 185nm wavelength is particularly suitable for applications requiring high UV utilization, such as lithography and UV spectral analysis

-

High thermal stability: it can withstand temperatures up to 1100°C without deformation, and its coefficient of thermal expansion is very small, suitable for use in environments with drastic temperature changes

-

Chemical purity: The material has good chemical stability and low impurity content, which effectively reduces the risk of contamination in sensitive applications such as semiconductor manufacturing

-

Low mechanical damping: The mechanical damping properties make it excellent in optical applications, allowing for sharper imaging and more accurate measurements

-

Wide range of optical applications: Suitable for various optical components such as lenses, Windows, prisms and mirrors, it is widely used for its excellent transmission properties in the visible and ultraviolet ranges

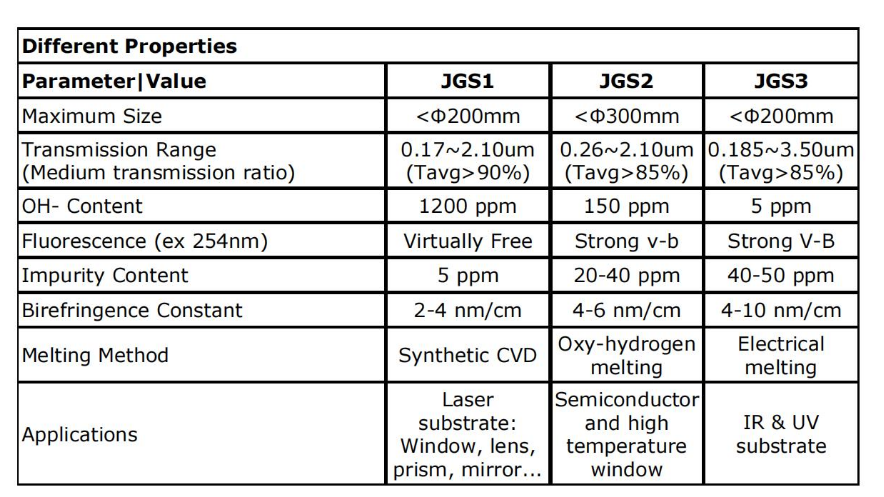

JGS quartz glass is a specialized type of optical glass made primarily from silica, known for its excellent physical and chemical properties. It includes several grades, notably JGS1, JGS2, and JGS3, each suited for different applications. Here’s an overview of JGS quartz glass:

Key Characteristics:

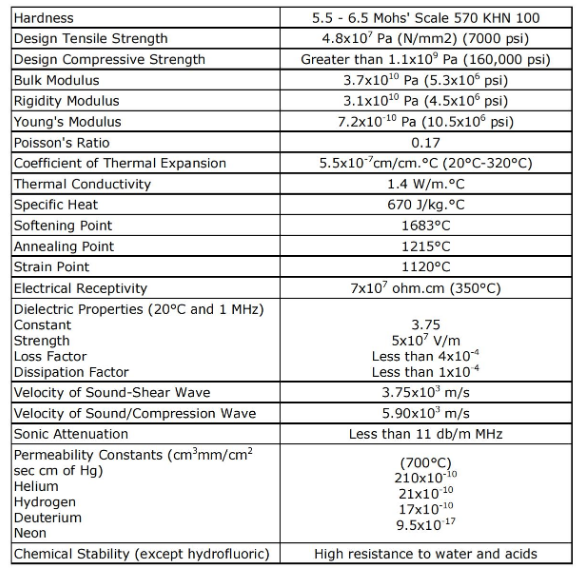

- High Temperature Resistance:JGS quartz glass has a softening point around 1730°C and can be used continuously at temperatures up to 1100°C. It can withstand short-term exposure to temperatures as high as 1450°C without damage.

- Chemical Stability:This glass is highly resistant to most acids (except hydrofluoric acid), exhibiting a corrosion resistance significantly greater than ceramics and stainless steel. Its chemical stability at high temperatures is unparalleled among engineering materials.

- Thermal Shock Resistance:With a low thermal expansion coefficient (approximately 0.58×10−6/K0.58×10−6/K), JGS quartz glass can endure rapid temperature changes without breaking, making it ideal for applications that involve thermal cycling.

- Optical Clarity:JGS quartz glass provides excellent optical transmission across a wide spectrum, from ultraviolet to infrared. The visible light transmission exceeds 93%, with UV transmission rates above 80%, making it suitable for various optical devices.

- Optical Homogeneity:The material exhibits high optical homogeneity with minimal impurities or bubbles, ensuring consistent performance in optical applications.

Detailed attribute:

JGS Quartz Glass Product Application:

JGS1 Quartz Glass:

- Optical Components: Used in the manufacturing of lenses, windows, prisms, and mirrors for optical devices.

- Laser Technology: Ideal for components in laser systems due to its high UV transmission and low absorption.

- Photolithography: Essential in semiconductor manufacturing processes where deep UV light is required.

- Spectroscopy: Utilized in spectrometers for precise measurements across a wide wavelength range (185-2500 nm).

JGS2 Quartz Glass:

- Condenser Optics: Employed in condenser lenses for microscopes and other optical instruments.

- High-Temperature Applications: Suitable for devices that operate under high temperature and pressure conditions.

- Optical Flats: Used in optical flats for calibration and testing of optical systems.

- Microscope Slides: Commonly found in laboratory settings for preparing samples.

JGS3 Quartz Glass:

- Infrared Applications: Transparent across ultraviolet, visible, and infrared spectral regions, making it suitable for IR optics.

- Bandpass Filters: Used in the production of optical filters that require precise wavelength selection.

- Multi-Spectral Devices: Ideal for applications needing a wide wavelength range from deep UV to mid-infrared (185-3500 nm).

- Optical Coatings: Employed in various optical coatings due to its excellent transmission properties.

Get Started Today!

Don’t miss out on the opportunity to elevate your projects with JGS quartz glass. Contact us now for samples or to discuss how our products can meet your specific needs.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.