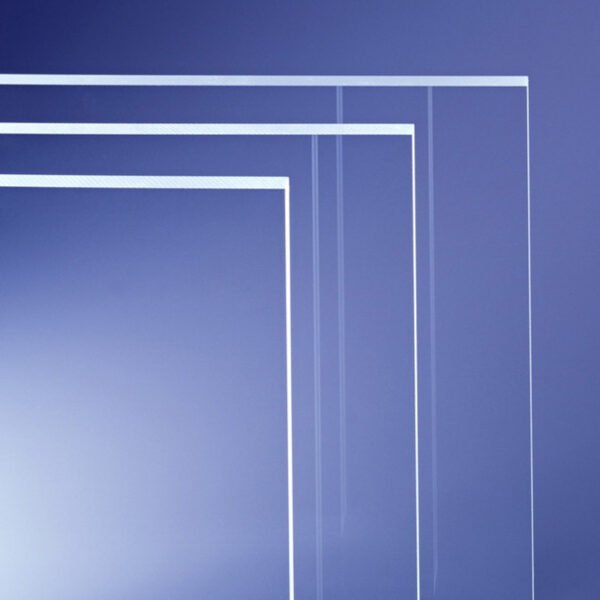

Domestic Alkali-Free Glass

Domestic alkali-free glass is a specialized type of glass characterized by its low alkali oxide content, typically less than 0.1%. This composition provides several advantages, particularly in high-tech applications.

-

High Chemical Stability: Alkali-free glass exhibits excellent resistance to chemical corrosion, making it suitable for use in harsh environments and applications where chemical durability is essential

-

Low Thermal Expansion: This type of glass has a low coefficient of thermal expansion, which allows it to maintain dimensional stability under varying temperature conditions, reducing the risk of cracking or deformation.

-

Enhanced Mechanical Strength: Alkali-free glass is known for its superior mechanical strength, which makes it ideal for applications requiring durability and resistance to impact.

-

Excellent Optical Clarity: The glass provides high transparency and clarity, making it suitable for optical applications such as display screens and lenses.

-

Environmentally Friendly: Being free from hazardous alkali metals, alkali-free glass aligns with modern environmental standards, making it a safer choice for both manufacturers and consumers.

Key Features

-

- Low Alkali Content: The minimal presence of alkali oxides ensures that the glass does not degrade the properties of thin films, making it suitable for sensitive electronic applications.

-

- High Thermal Dimensional Stability: Alkali-free glass exhibits a high strain point and a low thermal expansion coefficient, allowing it to maintain dimensional stability during high-temperature processes, such as those used in the production of liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs).

-

- Chemical Stability: The glass is chemically inert, making it resistant to various treating agents used in semiconductor processes. This property helps maintain the quality of the surface during manufacturing.

-

- Smooth Surface Finish: Glass substrates produced from alkali-free materials have flat precision surfaces, which are essential for high-quality optical and electronic applications.

-

- Environmentally Friendly: This type of glass is free from hazardous substances like arsenic (As) and antimony (Sb), aligning with modern environmental standards.

Applications

-

- Display Technology: Used as substrates for LCD and OLED displays, where dimensional stability and surface quality are critical.

-

- Thin Film Formation: Suitable for various thin film applications in electronics due to its chemical stability and low alkali content.

-

- Semiconductor Manufacturing: Employed in processes that require high precision and resistance to chemical treatments.

Overall, domestic alkali-free glass is an essential material in the electronics industry, providing reliability and performance in advanced display technologies and semiconductor applications.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.