Ultra-thin glass (UTG) and super-thin glass represent cutting-edge materials engineering that combines exceptional thinness with remarkable durability and optical performance. These advanced materials have transformed multiple industries, particularly consumer electronics, automotive displays, and medical devices. This comprehensive analysis examines their properties, manufacturing processes, applications, and future potential, highlighting key differences between UTG and super-thin glass technologies.

1. Understanding Ultra-Thin Glass (UTG)

1.1 Definition and Core Properties

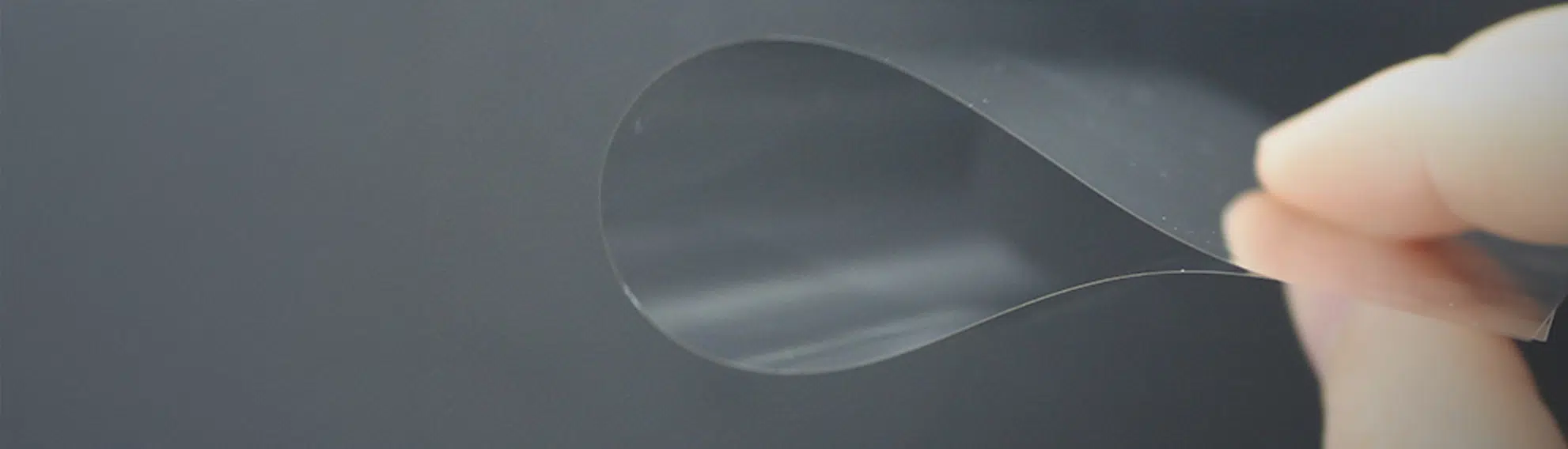

Ultra-thin glass is a sophisticated material characterized by its minimal thickness (typically 0.1mm to 1mm) while maintaining excellent mechanical strength, optical clarity, and flexibility. Unlike conventional glass, UTG combines glass rigidity with polymer-like adaptability, enabling revolutionary applications across various sectors.

Key Properties:

- Thickness: Ranges from 0.05mm (Corning Willow Glass) to 1mm

- Flexibility: Can bend to radii as small as 3mm without cracking

- Strength: Surface compression techniques (e.g., chemical strengthening) enhance durability

- Optical Performance: Light transmission exceeding 90%, minimal distortion for displays

- Weight: Up to 70% lighter than traditional glass of equivalent area

1.2 Manufacturing Technologies

1.2.1 Core Production Methods

Fusion Draw Process (Corning)

- Molten glass flows over a trough, forming a pristine sheet as it cools

- Advantages: Zero contact with surfaces, perfect flatness, thickness down to 0.03mm

- Applications: Foldable smartphone screens (e.g., Samsung Galaxy Z Flip)

Float Glass Process

- Glass floats on molten tin, creating uniform thickness

- Post-processing: Thinning via etching or grinding to achieve <0.5mm

- Uses: High-end displays (OLED TVs) and automotive panels

Chemical Thinning

- Hydrofluoric acid (HF) etches glass to precise thickness

- Critical for lab equipment and optical components requiring micron-level accuracy

Roll-to-Roll Processing

- Continuous production of flexible glass ribbons

- Ideal for wearable technology and flexible displays

1.2.2 Cutting and Shaping Techniques

Laser Cutting

- CO2 or femtosecond lasers create clean edges without microcracks

- Used for smartphone cover glass (e.g., iPhone ultra-thin edges)

Water Jet Cutting

- High-pressure water with abrasives shapes complex geometries

- Ideal for medical devices and sensors

Mechanical Scribing

- Diamond-tipped tools score glass, followed by controlled breaking

- Cost-effective for high-volume production

2. Super-Thin Glass: The Next Evolution

2.1 Definition and Differentiation

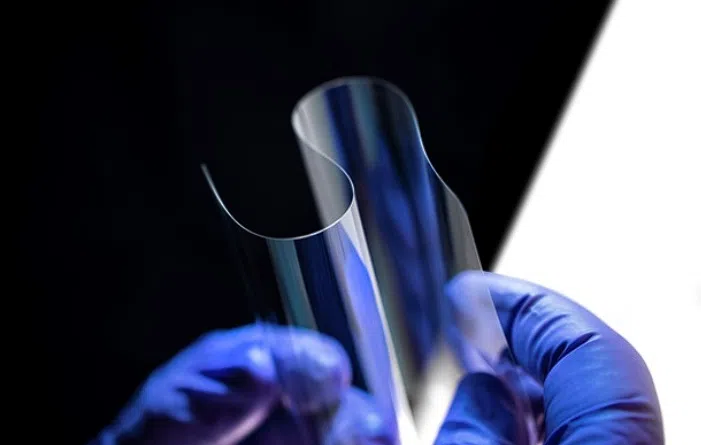

Super-thin glass represents the latest advancement in thin glass technology, pushing boundaries even further with thicknesses approaching 0.03mm. While the terminology sometimes overlaps with UTG, super-thin glass often refers to specialized formulations optimized for extreme thinness and flexibility.

Distinguishing Characteristics:

- Ultra-minimal thickness: Typically 0.03mm-0.07mm

- Enhanced flexibility: Can achieve folding radii under 1.5mm

- Specialized compositions: Modified chemical formulations for superior bend performance

- Advanced coatings: Nano-scale surface treatments for improved durability

2.2 Proprietary Manufacturing Processes

Micro-Gravity Assisted Thin-Film Technology

- Reduced gravitational influence during formation creates ultra-uniform thickness

- Primarily used in aerospace applications and premium consumer electronics

Vapor Deposition Glass Formation

- Molecular-level glass formation creates exceptionally pure, thin sheets

- Enables integration with sensitive electronic components

3. Comparative Analysis: UTG vs. Super-Thin Glass

3.1 Performance Metrics

FeatureUltra-Thin GlassSuper-Thin Glass Thickness 0.05mm-1mm0.03mm-0.07mm Flexibility Bend radius ~3mm Bend radius ~1.5mmDurabilityModerate scratch resistance Enhanced with special coatingsProduction CostModerateHighCommercial AvailabilityWidely availableLimited to premium applicationsHeat ResistanceUp to 600°CUp to 700°CTouch SensitivityGoodExcellent

3.2 Market Applications

Ultra-Thin Glass Dominance:

- Foldable smartphones (Samsung Galaxy Z series, Motorola Razr)

- Curved automotive displays

- Standard wearable technology

Super-Thin Glass Specialization:

- Ultra-premium flexible displays

- Advanced medical imaging devices

- Specialized optical systems

- Next-generation rollable displays

4. Applications Across Industries

4.1 Consumer Electronics

The evolution of display technology has been revolutionized by UTG and super-thin glass, enabling foldable smartphones, rollable displays, and wearable technology. Samsung’s adoption of UTG for its Galaxy Z Fold and Flip series marked a turning point in commercial viability.

Key Implementations:

- Foldable smartphone displays (both UTG and premium devices with super-thin glass)

- Curved display edges on premium smartphones

- Wearable technology displays with enhanced durability

- Tablet computers with reduced weight and enhanced portability

4.2 Automotive Industry

Modern vehicles increasingly incorporate thin glass technologies for displays, sensors, and aesthetic elements. The automotive sector values UTG for its combination of optical clarity and durability in demanding environments.

Notable Applications:

- Curved dashboard displays

- Head-up display (HUD) projection surfaces

- Touch-sensitive control panels

- Integrated sensor arrays with glass protection

4.3 Medical Technology

The medical field benefits from the unique properties of ultra-thin and super-thin glass in creating sophisticated diagnostic equipment and implantable devices.

Essential Uses:

- Microscope slides for high-resolution imaging

- Diagnostic device displays with exceptional clarity

- Implantable sensors with biocompatible glass encapsulation

- Microfluidic devices for laboratory diagnostics

4.4 Architectural and Design Applications

Innovative architectural applications leverage the visual appeal and practical advantages of thin glass technologies.

Creative Implementations:

- Lightweight decorative elements

- Smart windows with embedded displays

- Artistic installations with lighting integration

- Furniture with integrated display technology

5. Sustainability Considerations

5.1 Environmental Impact

Both UTG and super-thin glass offer environmental advantages compared to plastic alternatives, though manufacturing processes require careful consideration.

Environmental Factors:

- Reduced material usage compared to traditional glass

- Lower transportation emissions due to decreased weight

- Superior recyclability compared to plastic alternatives

- Energy-intensive production processes remain a challenge

5.2 Lifecycle Assessment

A complete evaluation reveals the complex sustainability profile of these advanced materials.

Lifecycle Considerations:

- Longer lifespan than plastic alternatives

- Nearly 100% recyclable at end-of-life

- Energy-intensive production partially offset by durability

- Reduced replacement frequency due to enhanced durability

6. Future Developments and Market Trends

6.1 Emerging Technologies

Research continues to push the boundaries of what’s possible with thin glass technology.

Promising Innovations:

- Self-healing glass surfaces for enhanced durability

- Embedded conductive elements for integrated circuitry

- Gradient composition glass with variable properties

- Composite materials combining glass with advanced polymers

6.2 Market Forecast

The global market for ultra-thin and super-thin glass is projected to experience substantial growth.

Market Projections:

- Compound annual growth rate exceeding 15% through 2030

- Expansion beyond consumer electronics into new sectors

- Price reduction as manufacturing scales and matures

- Increasing accessibility for mid-range product applications

7. Choosing Between UTG and Super-Thin Glass

7.1 Application-Specific Considerations

Decision factors when selecting between these advanced materials:

Selection Criteria:

- Required flexibility and folding performance

- Budget constraints and production volume

- Durability requirements and expected usage conditions

- Optical performance needs and display integration

Conclusion

Ultra-thin glass and super-thin glass represent remarkable achievements in materials science, enabling previously impossible product designs and applications. While UTG offers practical applications across a wide range of industries, super-thin glass pushes the boundaries of what’s possible in specialized premium applications. As manufacturing technologies advance and costs decrease, these materials will continue transforming industries and enhancing consumer experiences.

The ongoing innovation in this field points to an exciting future where the lines between rigid and flexible materials continue to blur, opening new possibilities for product design, functionality, and user experience across multiple sectors. Companies investing in mastering these technologies position themselves at the forefront of the next generation of display technology and specialized glass applications.