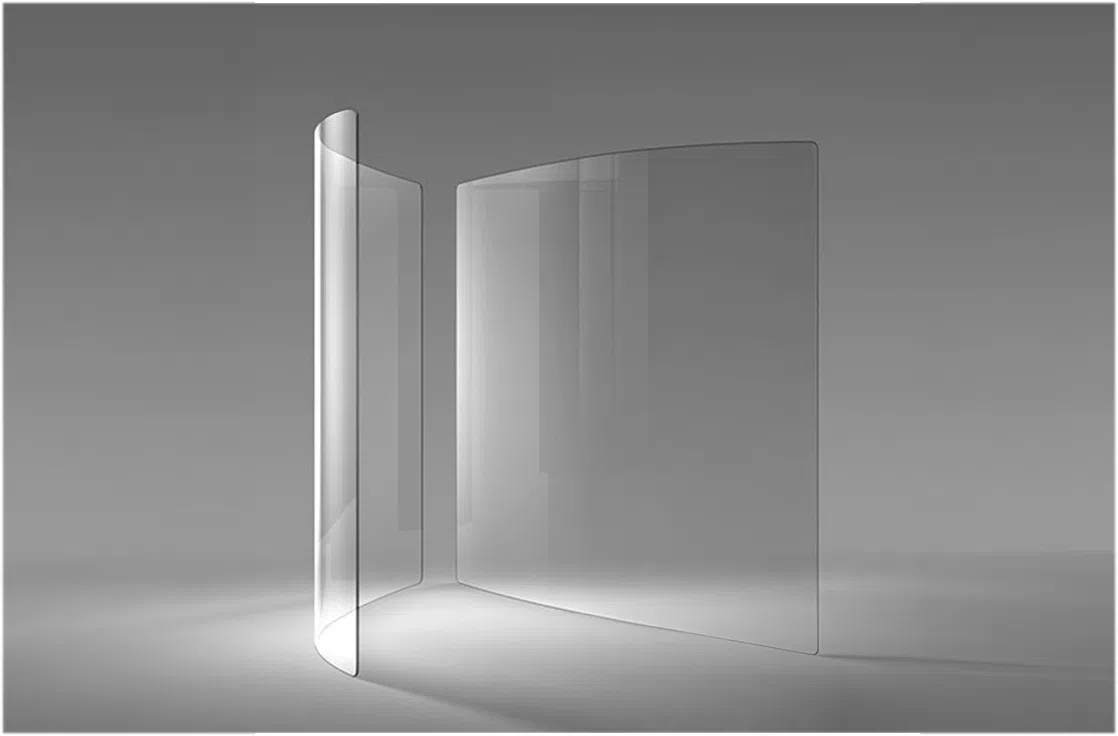

What is Curved Glass?

Curved glass (Bent Glass/Rounded Glass) is a specialty material shaped through thermal bending at 600-800°C. Key techniques include:

- 2.5D Curved Glass: Micro-curved edges for smartphones/wearables

- 3D Curved Glass: Multi-axis curvature for automotive/building applications

Breakthrough: Modern CNC thermal bending achieves ±0.1mm curvature tolerance while maintaining optical clarity.

Why Curved Glass Dominates Premium Desig

- 5X Structural Strength: Tempered curved glass withstands 200kg/m² wind pressure

- Aesthetic Superiority: Eliminates visual seams in museum walls/car sunroofs

- Functional Versatility: Compatible with Low-E coatings, lamination, and smart glass tech

- Space Optimization: Curved cabinet doors increase storage capacity by 22%

- Cost Efficiency: 30-50% higher initial cost but 3X longer lifespan

How do you manufacture curved giass?

Curved Glass Precision Manufacturing Process:

he manufacturing process of curved glass involves several critical steps to ensure high precision, durability, and optical clarity.

Glass Selection: Choosing the right type of glass (such as annealed, tempered, or laminated) for the bending process.

Cutting: The glass is cut to the required size using advanced CNC machinery to ensure accuracy.

Heating: The glass is heated to a specific temperature, making it soft and malleable for bending.

Shaping: The heated glass is then shaped into the desired curve using gravity bending or press bending techniques.

Cooling and Annealing: The glass is cooled slowly to avoid internal stress or cracks, enhancing its strength.

Cutting and Polishing: After cooling, the glass is cut to the final shape and polished to ensure smooth edges and surface clarity.

Quality Control: The glass undergoes testing for defects, impact resistance, and thermal shock to ensure durability and safety.

Yield Innovation: Smart temperature control boosts production yield from 65% to 92%.

Material requirements for curved glass

| Property | Technical Specifications |

|---|---|

| Thermal Stability | Low expansion, high softening point |

| Purity | High-grade SiO₂/Al₂O₃, uniform composition |

| Mechanical Strength | Chemically strengthened surface (ion exchange) |

| Optical Clarity | >90% transmittance, anti-reflective coating |

| Chemical Resistance | Durable silicate/aluminosilicate structure |

What kind of curved glass Specifications should be selected for different applications

| Application | Recommended Specifications | Key Features |

|---|---|---|

| Building Facades curved glass windows | 12-19mm laminated insulated glass | Wind/impact resistance |

| Automotive Sunroofs windscreen | 5mm tempered + PVB interlayer | Safety & optical clarity |

| Consumer Electronics Intelligent device | 0.7-1.2mm chemically strengthened | Scratch resistance, thin profile |

| Optical Instruments curved glassware | Borosilicate glass | Thermal/chemical stability |

Industry leading curved glass material

A. Corning Gorilla® Glass

- Grades: Victus® (7th Gen), Gorilla Glass 6

- Advantages:

- Aluminosilicate base with K+ ion exchange

- 2m drop resistance, 0.5mm thickness

- 92%+ light transmission, <1nm surface roughness

B. SCHOTT Xensation®

- Sodium aluminosilicate glass

- 900MPa surface stress, superior scratch resistance

C. AGC Dragontrail™ Pro

- Ultra-thin (0.3mm) aluminosilicate glass

- Ideal for curved automotive displays

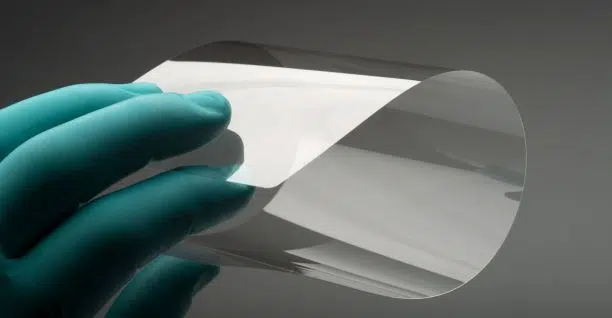

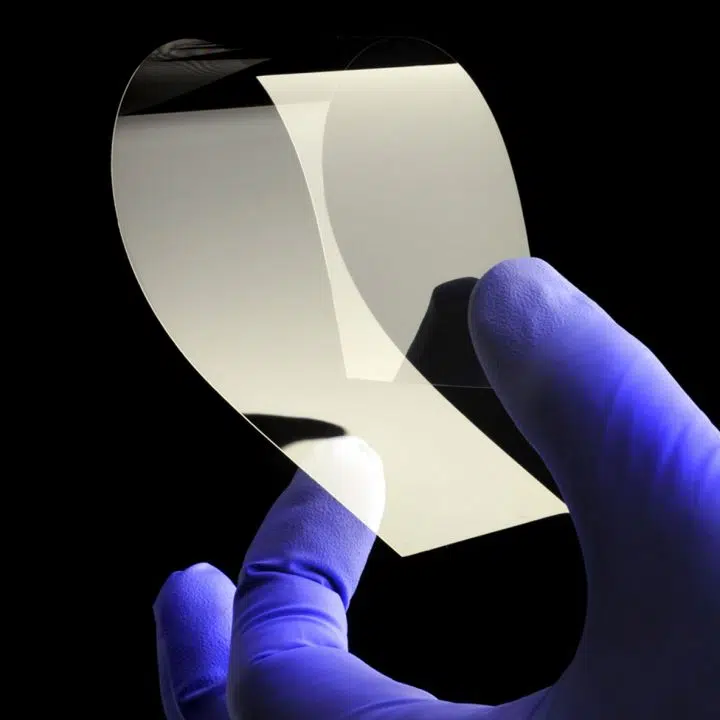

D. Ultra-Thin Glass (UTG)

- 30-70μm thickness, <3mm bend radius

- 200,000+ folding cycles

2.5D Curved Glass vs. Gorilla Curved Screen: Key Differences

2.5D Curved Glass

Advantages:

✅ Cost-effective for mass production

✅ Ergonomic edge design improves grip comfort

✅ Faster production cycle

Limitations:

❌ Vulnerable edge protection

❌ Prone to micro-chipping at curved regions

❌ Limited scratch resistance

Gorilla Curved Screen

Advantages:

✅ Exceptional impact resistance (2m drop protection)

✅ Ultra-slim profile (as thin as 0.2mm)

✅ Enhanced touch sensitivity and optical clarity

Limitations:

❌ 40-60% higher manufacturing cost

❌ Complex thermal forming process

❌ Longer lead times for custom orders

FAQs

Q1: Is curved glass more fragile?

A: Tempered curved glass has higher impact resistance – 6mm panels pass 110cm drop tests (JIS R3206).

Q2:ls curved glass strcnger?

A:Generally yes – when properly tempered, curved glass has 5-8× higher bending strength than flat glass due to optimized stress distribution. However, edge areas remain vulnerable to direct impacts.

Q3: Are curved windows expensive?

A: Yes, curved windows typically cost 30-50% more than flat equivalents due to specialized manufacturing (thermal bending, tempering). Custom designs add further costs.

Q4: How to cut curved glass?

A: Use CNC waterjet cutting (professional method) for precision. DIY attempts risk breakage – always consult certified glaziers for curved glass work.

Q5: When to replace curved glass?

A: Seek replacement for:

- Edge cracks >5cm

- Scratches >0.2mm deep

- Insulation layer fogging

Curved glass Future Trends

- Thinner Designs: 0.3mm flexible glass commercialization

- Multifunctional Integration: Solar-powered curved panels

- Smart Manufacturing: AI-powered defect detection (0.02mm accuracy)

As the leading curved glass manufacturer in China

We provide:

1.Premium Glass Material Supply based on your project

2.Custom Processing Solutions

| Service | Technical Capabilities | Applications |

|---|---|---|

| Thermal Bending | ±0.1mm curvature precision, 600-800°C CNC molding | Automotive windshields, architectural facades |

| CNC Machining | 5-axis waterjet cutting (±0.05mm tolerance) | Smartphone 3D covers, AR/VR lenses |

| Surface Treatment | Anti-reflective coating, AG/AF finishing, laser etching | Optical instruments, display panels |

| Ion Exchange | 900+ MPa surface compression layer | Foldable device screens |