1. What is Borofloat® Glass?

Borofloat® glass is a premium borosilicate glass developed by SCHOTT, manufactured using the float glass process. This process ensures a smooth surface, excellent flatness, and consistent thickness.

Key features:

- Low thermal expansion

- High resistance to thermal shock

- Excellent optical transparency

- Superior chemical durability

- Fire-polished surface finish

It’s widely recognized under the technical name Borofloat® 33, also referred to simply as Boro 33.

2. Understanding Boro 33 – The Science Behind Borofloat®

Boro 33 refers to the specific borosilicate glass composition with approximately 80% SiO₂, 13% B₂O₃, and a small amount of alkali and alkaline earth oxides.

Performance Advantages:

- Thermal stability: Continuous use at up to 450°C

- Coefficient of thermal expansion (CTE): 3.25 × 10⁻⁶/K

- High transmittance: ~92% in the visible range (400–700 nm)

- UV stability: Minimal autofluorescence, ideal for precision optics

- Chemical resistance: Resistant to acids, alkalis, and solvents

This makes Boro 33 glass an ideal substrate for demanding applications where dimensional stability and clarity are paramount.

3. Borofloat Glass Sheet – Formats for Versatility

We supply borofloat glass sheets in various standard and custom formats. The flatness and smooth surface make these sheets suitable for both structural and optical uses.

Available Specs:

- Thicknesses: 0.3 mm to 25 mm

- Sizes: 100×100 mm, 170×110 mm, 300×300 mm, and custom

- Finishes: Fire-polished, ground, or polished

Applications:

- Viewports and windows

- Substrates for mirrors and filters

- Laser equipment enclosures

- Heat shields in lighting and furnace systems

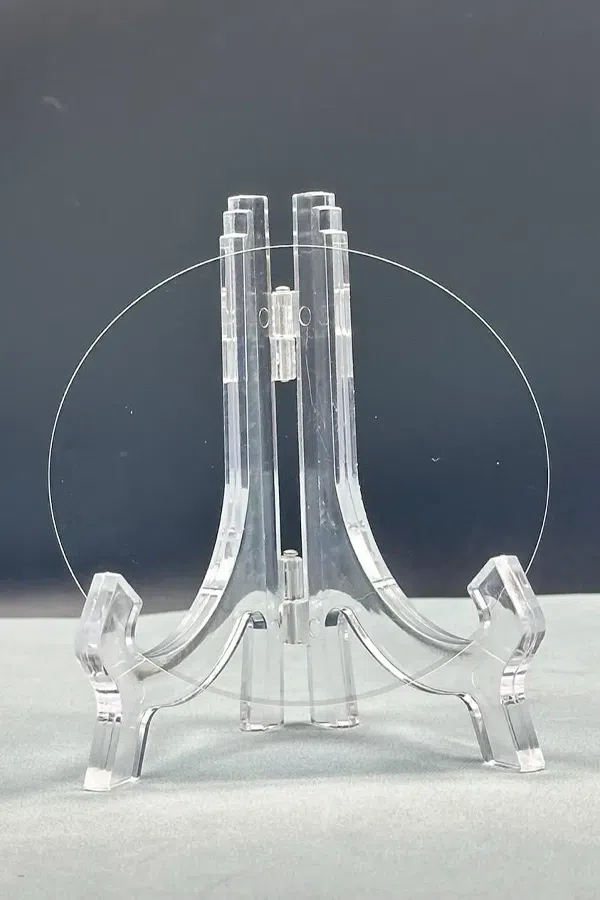

4. Borofloat Glass Wafer – The Backbone of Modern Micro Devices

Glass wafers made from Borofloat® 33 are used in cutting-edge industries such as microelectronics, MEMS, biotechnology, and AR/VR systems. These wafers are typically processed into circular disks with high thickness uniformity and surface precision.

Wafers We Provide:

- Sizes: 2″, 4″, 6″, 8″, and custom diameters

- Thickness range: 0.2 mm to 3 mm

- Surface finish: Single or double side polished

- Processing: Laser drilling, edge grinding, notches, slots, chamfering

Applications:

- MEMS devices and sensors

- Lab-on-a-chip (LoC) systems

- Optical microcavities

- Wafer-level packaging (WLP)

5. Application Scenarios of Borofloat® Glass

Borofloat® 33 finds use across a wide array of industries due to its combination of mechanical, optical, and chemical properties.

| Industry | Use Cases |

|---|---|

| Semiconductor | Carrier wafers, inspection windows, photolithography masks |

| Biomedical | Microfluidic chips, biosensor covers, culturing substrates |

| Optoelectronics | Laser windows, AR/VR lens substrates, optical filters |

| Laboratory Equipment | Watch glasses, microscope slides, cuvettes |

| Aerospace/Defense | HUD components, viewing ports, infrared and visible light systems |

| Analytical Systems | Spectroscopy cells, FTIR windows, interferometry plates |

6. Our Capabilities as a Borofloat Glass Supplier

As a custom optical glass processing factory, we not only supply borofloat glass sheet and glass wafer materials, but also offer:

- Precision cutting (square, round, special shapes)

- Drilling and slotting (CNC or laser, for holes, notches, chamfers)

- Polishing (optical-grade surfaces for high clarity)

- Etching and bonding prep

- Ultra-clean packaging for optical/medical use

- OEM service: From prototyping to mass production

We handle orders ranging from R&D-scale to industrial-scale supply and support fast, accurate delivery worldwide.

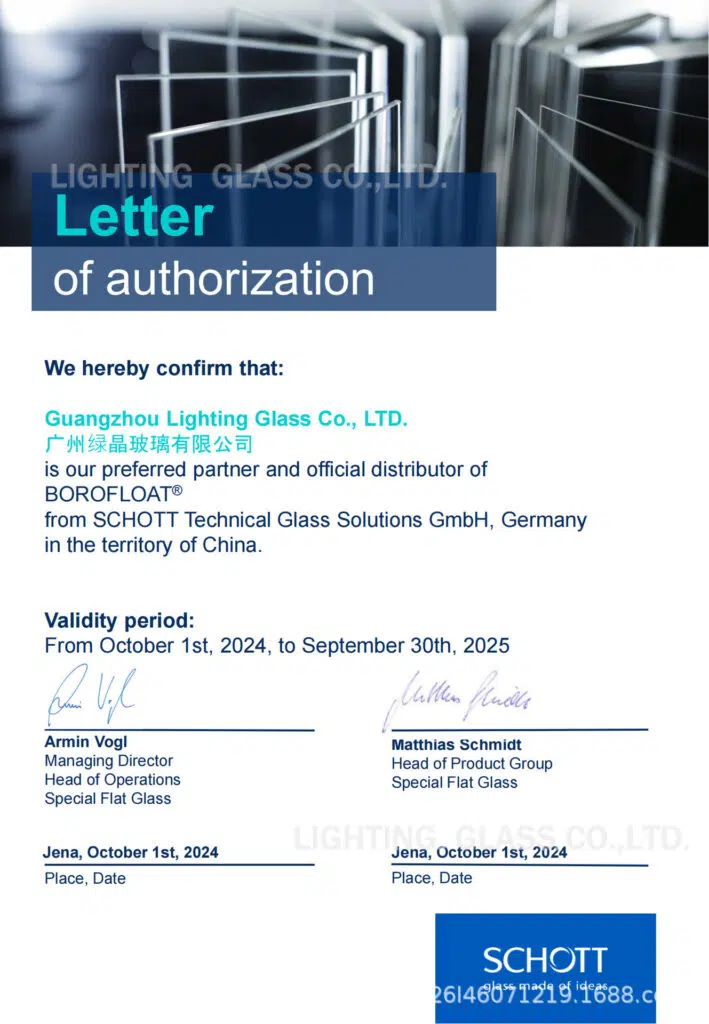

7. Why Professionals Choose Borofloat® 33 from Us

We are the agent of schott in China

With over 15 years of experience in glass customization, our factory provides:

✅ Expert material selection guidance

✅ Rapid turnaround and flexible MOQ

✅ ISO-controlled cleanroom packaging

✅ Competitive pricing and global logistics

✅ Technical support and design consultation

Whether you’re developing a new optical sensor, a microfluidic device, or scaling up your MEMS production, we’re your ideal borosilicate glass partner.

8. Conclusion – Borofloat® Glass as the Future-Proof Material

Borofloat® 33 combines thermal, chemical, and optical excellence, making it a go-to material for engineers and designers across industries. Whether in sheet form or as a precision glass wafer, its performance remains unmatched.

We pride ourselves on delivering both material and service excellence, helping innovators and manufacturers turn glass into performance.

Ready to start your next high-precision project?

Contact us today to discuss your needs for Borofloat glass sheet, glass wafer, or custom borosilicate glass components.