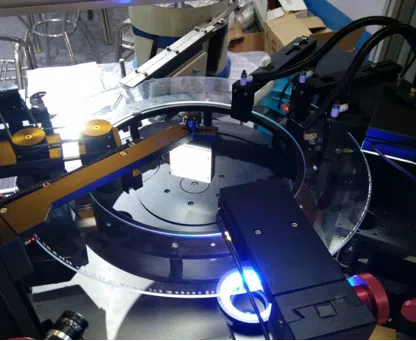

Optical sorting glass plates serve as the essential working platform for optical image sorting machines, where materials are conveyed from vibrating feeders onto the glass surface for imaging, sensing, detection, and sorting operations.

What Are Optical Sorting Glass Plates?

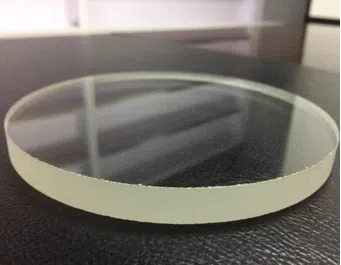

Optical sorting glass plates are specialized precision glass components designed as working platforms for optical sorting equipment. These high-performance glass plates enable accurate detection and sorting of magnetic materials, precision screws, nuts, small metal components, and other precision electronic parts through advanced optical imaging systems.

Performance Requirements for Optical Sorting Glass Plates

Optical Performance

- High Parallelism Tolerance – Maintains consistent imaging focus and measurement accuracy.

- Good Optical Transmittance – Ensures sufficient light transmission for clear imaging.

- Scratch Resistance – Reduces surface wear during continuous contact with materials.

Mechanical Precision

- Concentricity and Roundness – Supports stable rotation and alignment.

- Accurate Hole Positioning – Matches machine assembly requirements.

- Edge Grinding and Chamfering – Improves durability and handling safety.

Why Use BOROFLOAT® 33 Glass for Optical Sorting?

BOROFLOAT® 33 is a suitable choice for optical sorting glass plates due to:

- Stable Parallelism – Helps maintain detection accuracy in optical sorting.

- Good Optical Transmission – Supports high-quality imaging and reliable detection.

- Surface Hardness – Provides better resistance to scratches, reducing maintenance needs.

Custom Optical Sorting Glass Plate Services

We offer manufacturing and processing services for optical sorting glass plates, including:

- Sourcing of suitable glass materials

- Precision CNC machining

- Custom sizes and specifications

- Dimensional and surface quality testing

- Secure packaging and shipping

Our production capabilities ensure that the glass plates meet both optical and mechanical requirements for reliable use in sorting applications.