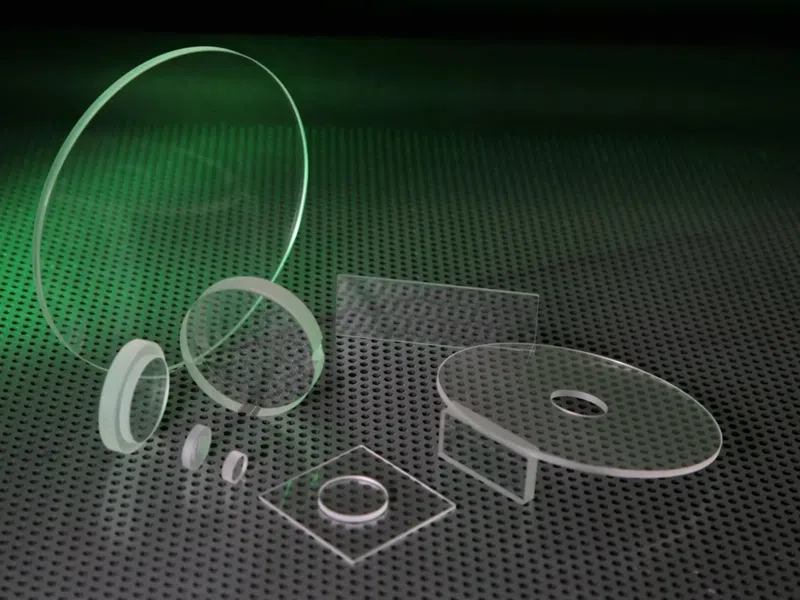

When we think about high-quality glass—whether in a telescope lens, a smartphone screen, or a microchip—one thing they all have in common is a flawless, smooth surface. That’s where glass polishing comes in. This crucial process transforms rough, cut, or machined glass into clear, optically refined components with exceptional surface precision. Whether you’re working in optics, semiconductors, or architectural design, understanding how glass is polished helps you appreciate the craftsmanship and technology behind the materials you rely on.

Why Glass Polishing Matters More Than You Might Think

You may start with a high-grade piece of glass, but if it hasn’t been polished, chances are it’s covered in micro-scratches, haze, and other surface irregularities that interfere with performance. Polishing removes these imperfections, boosting transparency and ensuring a surface flatness that’s critical for optical bonding, coatings, and high-precision applications.

For industries like photonics, microfluidics, and semiconductor manufacturing, the surface condition of the glass isn’t just about appearance—it affects everything from light transmission and reflectivity to adhesion and durability. Even microscopic surface defects can cause coating failure or interfere with alignment in sensitive systems.

How Glass Is Polished: A Closer Look at the Techniques

There are several methods used to polish glass, and each has its place depending on the type of glass, the desired finish, and the specific application.

Mechanical polishing is the most widely used approach, particularly for flat glass panels, architectural features, or general-purpose glass surfaces. In this method, abrasives like aluminum oxide, silicon carbide, or diamond paste are applied using polishing pads made from felt or polyurethane. Deionized water is usually used as a lubricant to help carry away debris and reduce heat.

For more delicate applications—like optical components, wafers, or lab glassware—chemical polishing offers a non-mechanical solution. This process typically uses hydrofluoric acid-based chemicals to gently etch away surface imperfections. While highly effective, it must be done in a tightly controlled environment, given the toxicity and volatility of the chemicals involved.

Then there’s chemical-mechanical polishing, or CMP. This method is especially popular in the semiconductor and photonics industries, as it combines both the mechanical action of fine abrasives and the chemical interaction of reactive slurries to achieve ultra-smooth finishes. CMP is often used for materials like borosilicate and fused silica, where achieving sub-nanometer surface roughness is critical.

Cerium oxide, in particular, is the preferred polishing medium for many optical applications because of its ability to deliver an incredibly smooth finish without damaging the material.

In small-batch or prototype work, manual glass polishing still has its place. Skilled technicians can use hand pads or felt wheels with cerium oxide to restore scratched surfaces, prepare custom optics, or fine-tune components that can’t easily be processed on a machine. It’s a slower process, but it allows for flexibility and a high level of control, especially when working with complex geometries or fragile materials.

Polishing Techniques for Borosilicate, Quartz, Float, and Sapphire Glass

Not all glass behaves the same during polishing. For example, borosilicate 3.3 (like Pyrex) is commonly used in scientific and industrial settings due to its thermal stability and can be polished effectively using cerium oxide. Quartz glass, or fused silica, is more challenging due to its hardness and purity requirements, often needing ultra-fine abrasives and tightly controlled conditions. Float glass, typically used in architectural applications, can benefit from surface and edge polishing to improve clarity and aesthetics.

Tempered glass, however, presents a unique challenge—it cannot be polished after tempering. If any polishing is needed, it must be completed before the glass undergoes the tempering process. Sapphire glass, known for its extreme hardness, requires diamond-based abrasives and advanced equipment like CNC machines to achieve a polished finish.

Equipment Behind the Scenes

Depending on the project scale and precision level, different equipment may be used. Large flat glass sheets often go through dedicated polishing machines, while high-precision components—like lenses or microfluidic chips—require CNC polishing centers capable of sub-micron accuracy. For edge finishing, especially in display and architectural glass, edge polishers are used to improve safety, aesthetics, and functionality. In labs or custom shops, hand tools remain invaluable for final touch-ups or small-scale jobs.

Real-World Applications of Glass Polishing

You’ll find polished glass in places you might not expect. In optics, lenses, prisms, filters, and windows depend on flawless surfaces to perform properly. In the world of semiconductors and MEMS, ultra-flat glass wafers are the foundation for complex devices. Scientific laboratories rely on polished slides, beakers, and inspection windows that resist scratching and ensure clarity. Even your kitchen or bathroom may feature polished glass panels in ovens or shower enclosures. And of course, smartphones, tablets, and smartwatches rely on carefully polished display glass for both looks and durability.

Frequently Asked Questions (FAQ)

Q: What is the best polishing material for optical glass?

A: Cerium oxide is widely regarded as the most effective and reliable choice for polishing optical glass due to its excellent balance of mechanical and chemical action.

Q: Can tempered glass be polished?

A: Unfortunately, no. Polishing must be done before tempering, as post-tempering polishing compromises the integrity and safety of the glass.

Q: What’s the difference between mechanical and chemical polishing?

A: Mechanical polishing uses abrasive materials to grind and smooth the surface. Chemical polishing uses acids or etchants to dissolve surface irregularities. Chemical-mechanical polishing (CMP) combines both for enhanced precision.

Q: Do you offer custom borosilicate glass polishing?

A: Absolutely. We polish borosilicate 3.3 to exact specifications, including ultra-flat finishes, CNC-shaped edges, and custom features like holes or markings.

Why Professionals Choose LIGHTING

At LIGHTING, we’re passionate about precision. We specialize in high-quality polishing services for borosilicate, quartz, and other optical glasses. Whether you need ultra-smooth surfaces for optical filters, custom wafer polishing for electronics, or CNC edge finishing for display glass, our team is ready.

Our capabilities include polishing glass to less than 1 nm Ra surface roughness, supporting wafer sizes from 2″ to 8″, and providing customized polishing and scratch removal services. We work with certified abrasives like high-purity cerium oxide, and all sensitive components are handled in cleanroom-grade environments. Our goal is not just to meet industry standards—but to exceed them.

Final Thoughts

Glass polishing may be one of the final steps in glass processing, but it’s also one of the most important. A well-polished surface defines the performance, reliability, and visual clarity of the final product—whether it’s heading into space, powering a microchip, or sitting on your kitchen counter.

If you’re looking for consistent quality, advanced capabilities, and a partner who understands the science behind the shine, LIGHTING is here to help.