CORNING Eagle XG

In modern display technology and high-end electronics, CORNING Eagle XG glass is undoubtedly a representative of innovation and high quality. As a leading global supplier of high-performance glass, Corning’s Eagle XG series glass has become a core component of many advanced electronic devices. Whether for smartphones, tablets or high-end displays, this glass has won unanimous praise from the industry with its excellent performance and unique advantages. This article will discuss in detail the characteristics, technical advantages, application areas and how CORNING Eagle XG glass stands out in the market.

-

Environmental protection features:Eagle XG is free of heavy metals (such as arsenic, antimony, barium and halides) and meets environmental standards, reducing environmental impact.

-

High light transmittance:The glass has a visible light transmittance of more than 92%, ensuring a clear visual effect in display applications.

-

Excellent chemical durability:Eagle XG shows good tolerance to a variety of chemical agents, suitable for use in harsh environments, extending the service life of the product.

-

Low density and lightweight:Its density is about 2.38 g/cm³, allowing the Eagle XG to create thinner, lighter display panels while maintaining strength.

-

Excellent thermal stability:The glass has good thermal expansion characteristics and high softening point, which enables it to work stably in high temperature environments and is suitable for various electronic and optoelectronic devices.

What Is Corning Eagle XG® Glass?

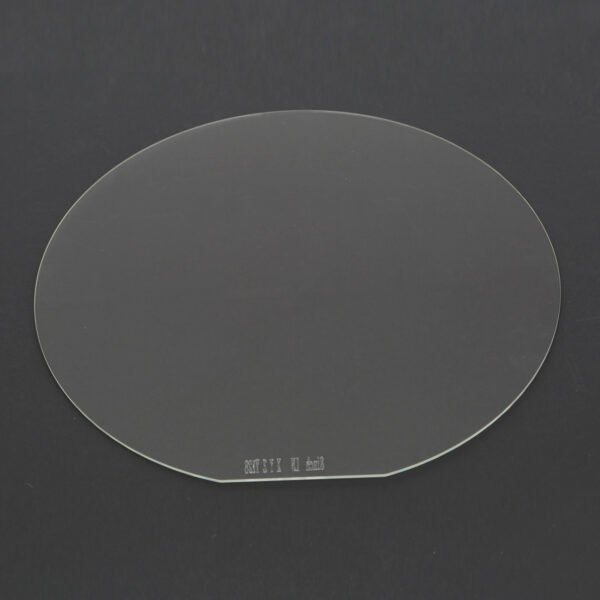

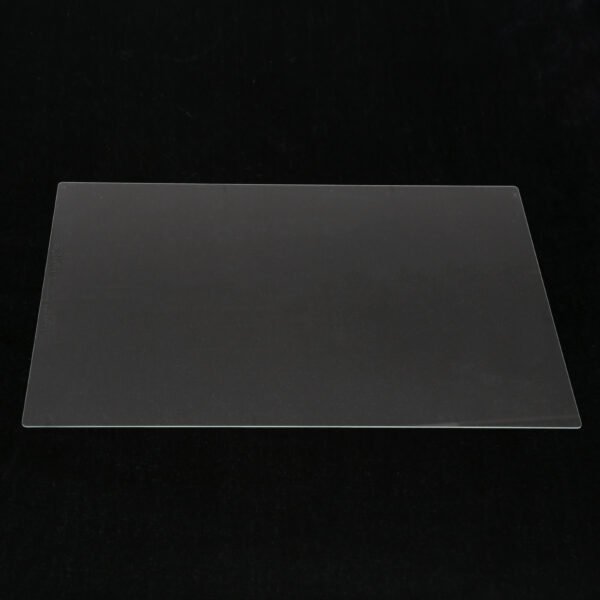

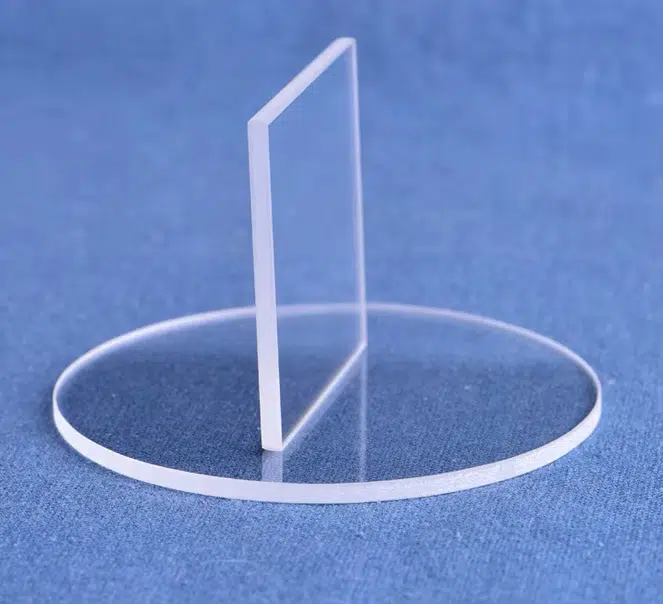

Corning Eagle XG glass is a premium alkali-free aluminoborosilicate substrate specifically engineered for advanced display applications and precision optical components. This ultra-flat, dimensionally stable glass offers exceptional surface quality and outstanding thermal properties, making it the preferred choice for high-resolution displays, semiconductor wafers, and demanding optical applications.

Compared with conventional soda-lime glass, Corning Eagle XG delivers superior flatness, enhanced chemical durability, and better thermal shock resistance, enabling manufacturers to achieve higher yields and superior product performance.

Key Properties of Corning Eagle XG® Glass

- Ultra-Flat Surface: Surface roughness <0.5 nm Ra for precision applications

- Alkali-Free Composition: Prevents alkali migration in electronic devices

- Excellent Thermal Stability: Low coefficient of thermal expansion (3.2 ppm/°C)

- Superior Chemical Resistance: Outstanding durability against acids and bases

- High Transmission: >92% visible light transmission for optical clarity

- Dimensional Precision: Maintains tight tolerances under thermal cycling

Custom Optical Glass Manufacturer – Corning Eagle XG® Specialist

As a leading Corning Eagle XG manufacturer in China, we specialize in precision processing and custom fabrication of Corning Eagle XG substrates for diverse industrial applications. Our state-of-the-art facilities and experienced engineering team deliver tailored custom optical glass solutions with guaranteed quality and competitive pricing for global customers.

We proudly support universities, laboratories, and research institutes worldwide, providing not only high-performance Eagle XG glass but also technical guidance and collaborative customization to accelerate innovation in optics, photonics, and electronics.

Get a Quote for Corning Eagle XG Processing

Applications of Corning Eagle XG® Glass

We serve multiple industries requiring precision optical glass and advanced substrates, including:

- Display Technology: LCD panels, OLED displays, touch screens, flexible displays

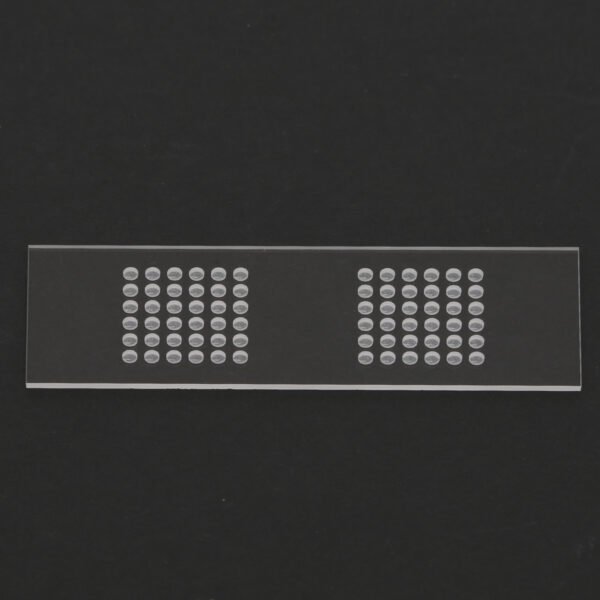

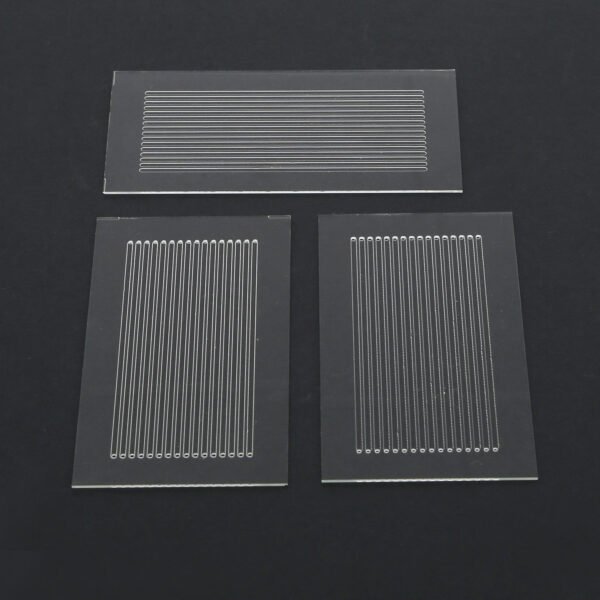

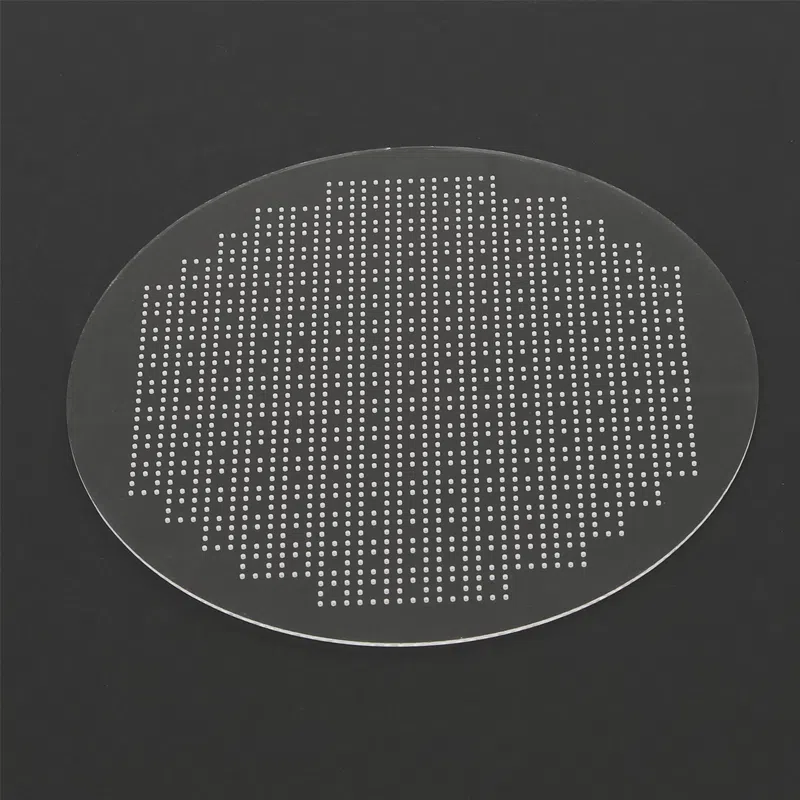

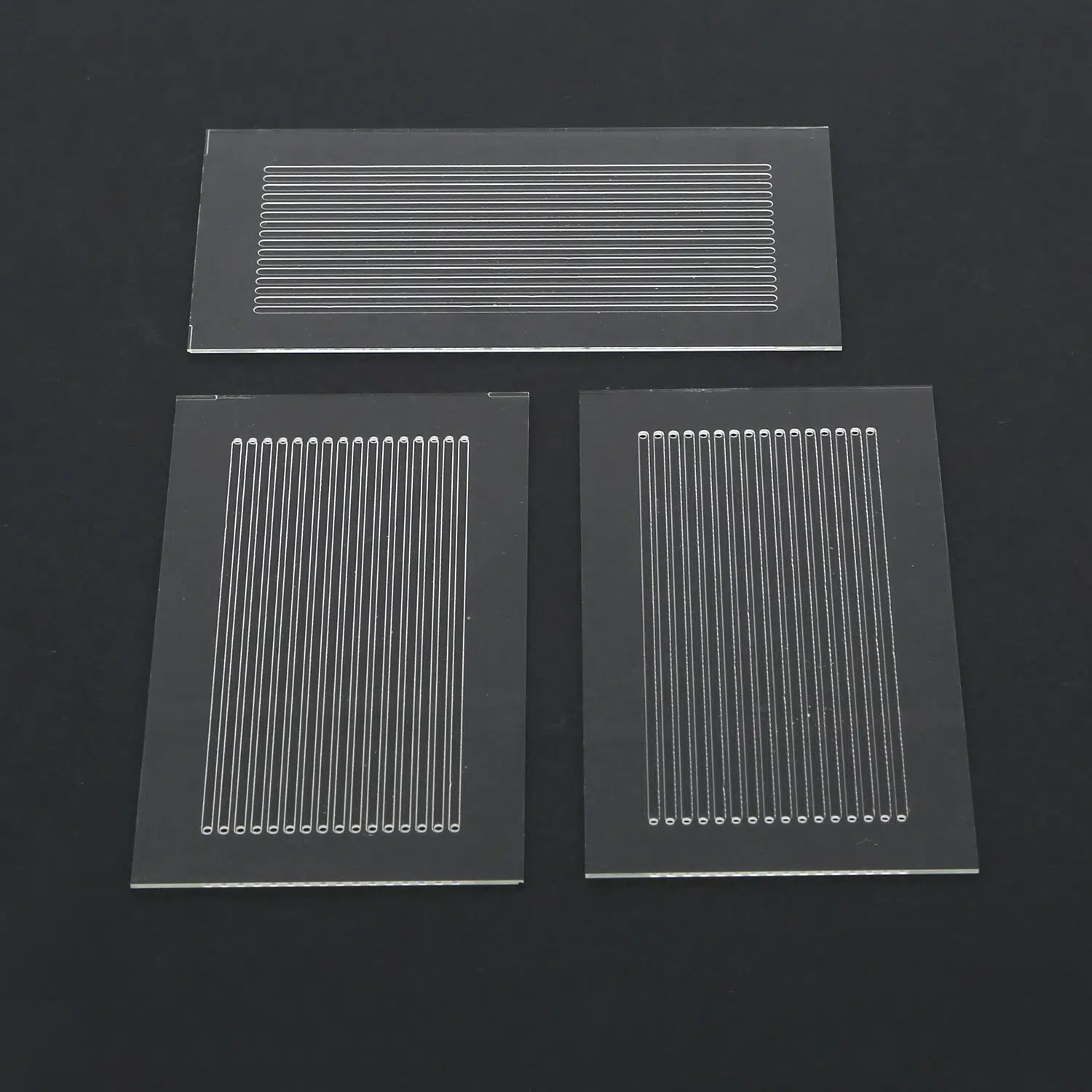

- Semiconductor & Electronics: Corning Eagle XG wafer processing, IC substrates, MEMS devices

- Optical Components: High-precision windows, cover glass, optical filters

- Scientific Instruments: Laboratory equipment, analytical instruments, microscopy

- Industrial Applications: Protective windows, sight glasses, specialized optical elements

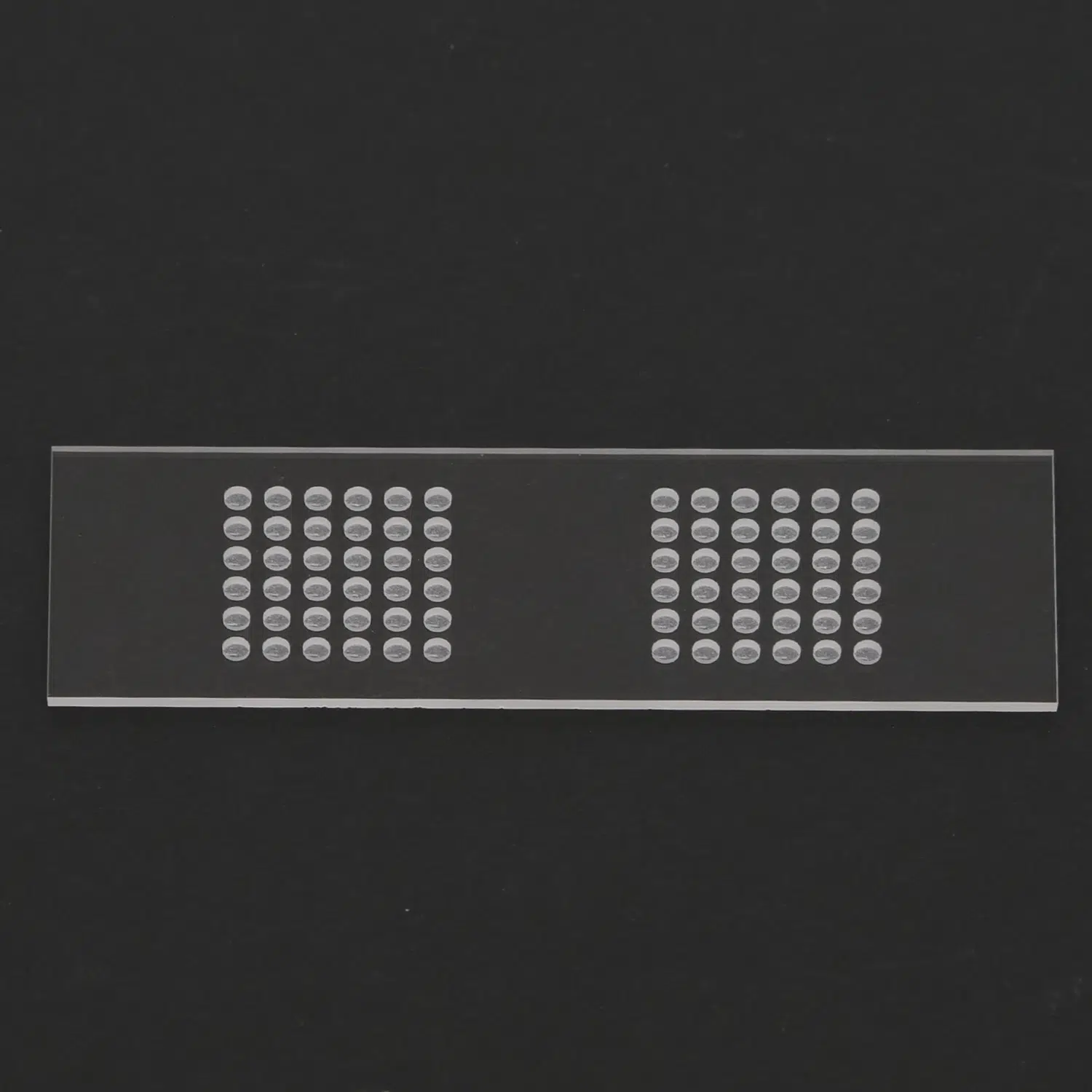

Corning Eagle XG® Process Capabilities

We offer end-to-end process services for Corning Eagle XG glass, including:

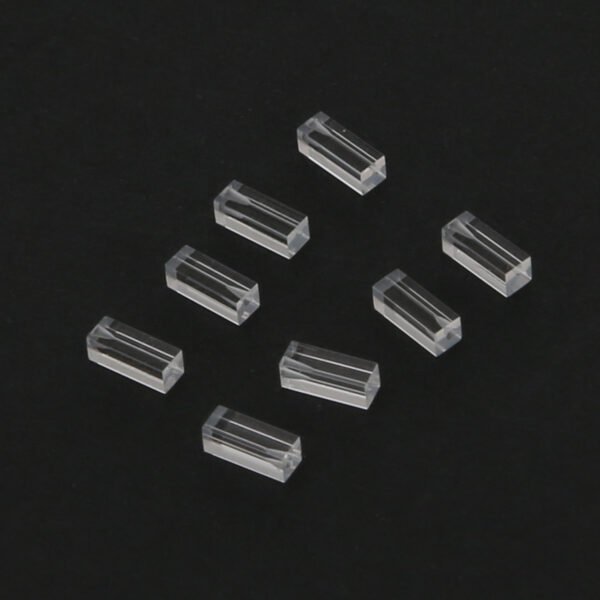

Precision Cutting & Shaping

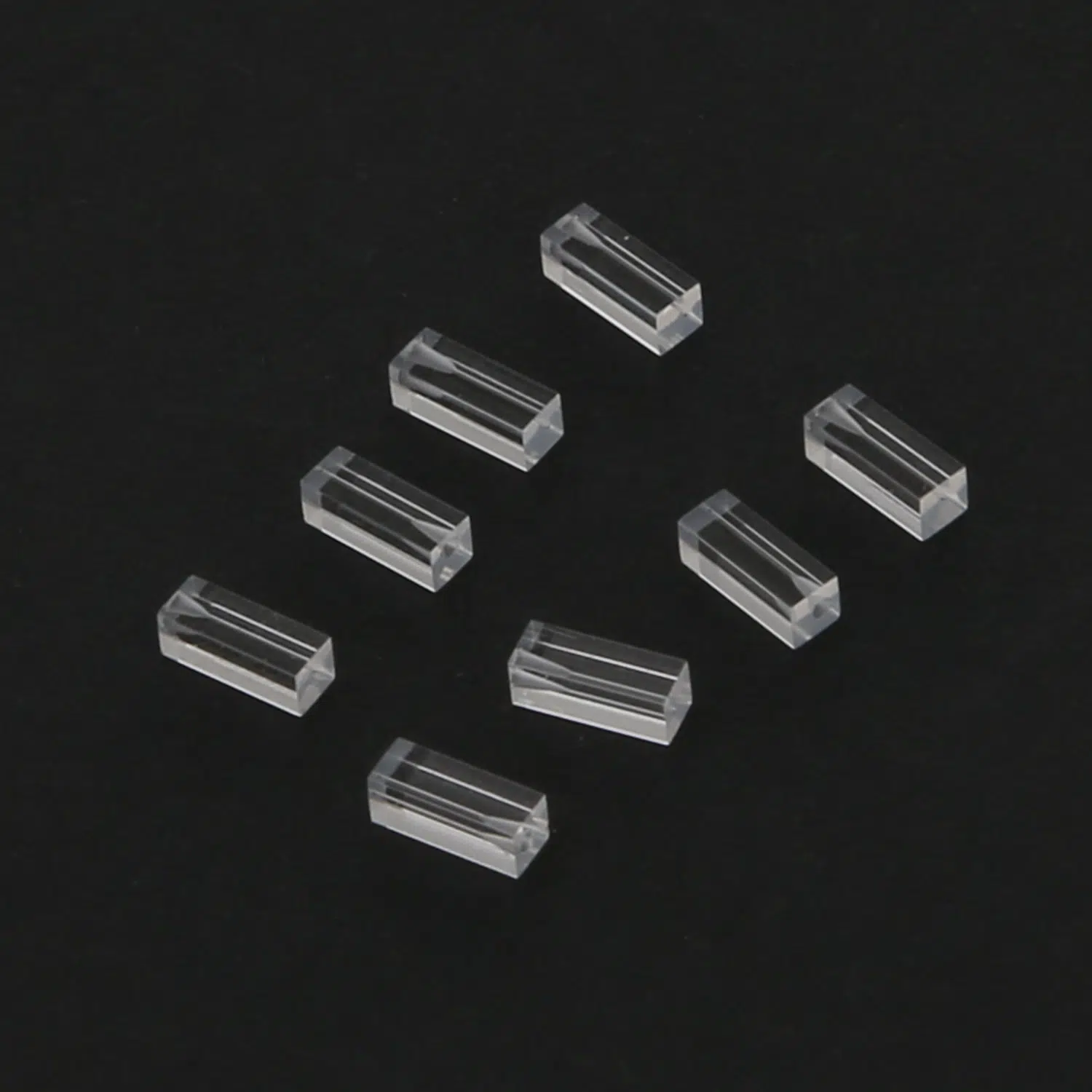

Laser cutting for complex geometries, diamond scribing and breaking, and CNC machining for custom shapes.

Surface Processing

Chemical strengthening, anti-reflective (AR) coating, hydrophobic/oleophobic treatments, ITO sputtering and patterning.

Quality Control

Flatness measurement (<1 μm TTV), surface roughness analysis, optical transmission testing, stress analysis, and quality certification.

Materials and Specifications We Offer

| Property | Specification | Typical Applications |

|---|---|---|

| Thickness Range | 0.1 mm – 5.0 mm | Display substrates, wafers |

| Size Capability | Up to 1500 mm × 1850 mm | Large format displays |

| Surface Quality | <0.5 nm Ra | Precision optics |

| Flatness | <1 μm TTV | Semiconductor processing |

| Edge Quality | Polished / Ground options | Custom requirements |

Custom dimensions available per customer drawings and specifications. Prototype to high-volume production capabilities.

Corning Eagle XG® China Agent – Your Trusted Partner in China

As an authorized Corning Eagle XG® China Agent (China distributor), we provide:

Direct Factory Pricing & Fast Delivery

Technical Support & Application Engineering

Custom Processing & Value-Added Services

Quality Assurance & ISO 9001:2015 Certification

Flexible MOQ from Prototypes to Mass Production

Export Documentation & Global Shipping

Why Choose Our Corning Eagle XG® Services?

Advanced Manufacturing Capabilities

Our precision processing equipment and clean room facilities ensure consistent quality for Corning Eagle XG® wafer and substrate applications.

Technical Expertise

Experienced optical engineers provide design optimization and process consulting for your specific requirements.

Quality Assurance

Comprehensive inspection and testing protocols guarantee dimensional accuracy and optical performance.

Global Supply Chain

Efficient logistics and export capabilities serve customers worldwide with competitive lead times.

Competitive Pricing Advantage

We offer factory-direct pricing , allowing us to deliver cost-effective solutions without compromising on quality — ideal for both research-scale prototyping and industrial mass production.

Frequently Asked Questions (FAQ)

Q: What makes Corning Eagle XG® different from regular optical glass?

A: Corning Eagle XG is specifically designed for display and semiconductor applications with alkali-free composition, ultra-flat surfaces, and superior dimensional stability compared to conventional optical glass.

Q: Can you process Corning Eagle XG® wafers for semiconductor applications?

A: Yes, we offer complete Corning Eagle XG wafer processing including precision cutting, edge polishing, cleaning, and packaging for semiconductor and MEMS applications.

Q: What is the minimum order quantity for custom Corning Eagle XG®processing?

A: We support both prototyping (as low as 1 piece) and high-volume production. MOQ depends on specific processing requirements and can be discussed based on your project needs.

Q: Do you provide coating services for Corning Eagle XG® substrates?

A: Yes, our Corning Eagle XG process capabilities include anti-reflective coatings, ITO sputtering, hydrophobic treatments, and other specialized coatings for display and optical applications.

Q: What quality certifications do you maintain for Corning Eagle XG® processing?

A: We maintain ISO 9001:2015 certification and follow strict quality control protocols including dimensional inspection, optical testing, and surface quality verification for all processed substrates.

Q: How do you ensure the flatness requirements for precision applications?

A: Our advanced metrology equipment measures flatness to sub-micron accuracy, and our processing techniques maintain the inherent flatness of Corning Eagle XG® glass throughout fabrication.

Q: Can you handle both small prototype and large volume production orders?

A: Absolutely. As a flexible custom optical glass manufacturer, we support everything from single prototype pieces to high-volume production runs with consistent quality and competitive pricing.

Q: What are the typical lead times for Corning Eagle XG® custom processing?

A: Lead times vary based on complexity and quantity, typically ranging from 1–2 weeks for standard processing to 3–4 weeks for complex custom specifications. Rush orders can be accommodated upon request.

Q: Do you ship Corning Eagle XG® products internationally?

A: Yes, we have extensive export experience and can ship globally with proper packaging and documentation. We serve customers in North America, Europe, Asia, and other regions worldwide.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.