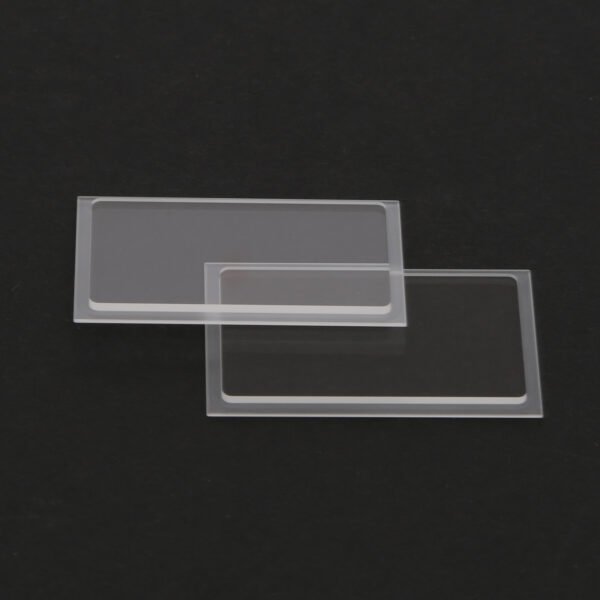

SCHOTT AF32

SCHOTT AF32 is an advanced optical glass with exceptional properties, widely used in a variety of applications, including photography, microscopy, and high-precision optical instruments. It is known for its low dispersion and high transmittance, making it ideal for producing high-quality optical components such as lenses, prisms, and optical filters. AF32 glass offers excellent performance in the visible light spectrum, ensuring clear and precise images.

-

Low Dispersion: SCHOTT AF32 exhibits low dispersion, which helps reduce chromatic aberration in optical systems, ensuring sharp and high-quality images.

-

High Transmittance: The glass offers excellent light transmission across the visible spectrum, allowing more light to pass through, which enhances the brightness and clarity of optical devices.

-

Superior Optical Clarity: AF32 is known for its exceptional clarity, making it ideal for applications where image sharpness and precision are critical.

-

High Stability: The material is thermally stable and resistant to environmental factors, ensuring reliable performance over a wide range of temperatures.

-

Versatility: Due to its excellent optical properties, SCHOTT AF32 is suitable for a variety of applications, including precision optics, medical imaging, and scientific instruments.

Customizable Thickness Options of SCHOTT AF32® Glass

As a premier supplier and processor of SCHOTT AF32® Glass, we provide tailored thickness configurations to meet diverse project demands. Our standard offerings include:

-

- 0.3 mm (300 µm) – Combines ultra-thin design with robust durability, ideal for high-reliability electronics.

-

- 0.5 mm (500 µm) – Optimized for structural stability in automotive and aerospace applications.

-

- 0.7 mm to 1.0 mm – Suited for multilayer systems and industrial-grade components.

-

- Custom thicknesses up to 1.1 mm – Available for specialized high-load or thermal management applications.

All thicknesses are precision-cut and edge-treated using advanced CNC or laser technologies. Custom coatings and surface enhancements are applied based on functional requirements.

| Thickness (mm) | Specification (µm) | Primary Applications | Processing Options | Available Coatings |

|---|---|---|---|---|

| 0.3 mm | 300 µm | High-Reliability Electronics: | CNC Machining | Anti-Reflective Coating |

| • Automotive Displays | Laser Cutting | Anti-Fingerprint Coating | ||

| • Medical Device Sensors | Thermal Tempering | |||

| 0.5 mm | 500 µm | Structural Stability: | Precision Grinding | Hardened Scratch-Resistant Coating |

| • Aerospace Instrumentation | Chemical Strengthening | UV-Blocking Coating | ||

| • Industrial Control Panels | ||||

| 0.7–1.0 mm | 700–1000 µm | Multilayer/High-Temperature Systems: | Multi-Axis Milling | Thermal Barrier Coating |

| • Semiconductor Packaging | Lamination Bonding | Conductive Coating (Custom) | ||

| ≤1.1 mm | ≤1100 µm | Specialized Heavy-Duty Applications: | Ultrasonic Drilling | EMI Shielding Coating |

| • Power Electronics Heat Spreaders | 3D Shaping | Custom Dielectric Coatings (On Request) |

Diverse Applications of SCHOTT AF32® Glass

We collaborate with clients globally to integrate SCHOTT AF32® Glass into innovative solutions across industries:

-

- Automotive Displays and HUDs SCHOTT AF32® serves as a high-strength substrate for curved dashboards, heads-up displays (HUDs), and touch interfaces, withstanding vibrations and extreme temperatures (-40°C to 150°C).

-

- Medical and Biotech Devices Used in endoscopic imaging, lab-on-chip systems, and sterilizable sensor housings, leveraging its chemical resistance and biocompatibility.

-

- Semiconductor Packaging As a carrier wafer or interposer in 2.5D/3D IC packaging, enabling fine-pitch interconnects and thermal stability during reflow processes.

-

- Aerospace and Defense Deployed in cockpit avionics, armored vision systems, and satellite components due to its lightweight properties and radiation resistance.

-

- Energy and Power Electronics Functions as insulating substrates in IGBT modules and high-voltage capacitors, offering exceptional dielectric strength and thermal conductivity.

-

- Consumer Electronics Integrated into ultra-slim smart devices, ruggedized tablets, and AR/VR optics, balancing aesthetics with drop resistance.

-

- Industrial IoT and Sensors Used in harsh-environment pressure sensors, pH-resistant industrial monitors, and MEMS-based actuators.

Why Partner with Us for SCHOTT AF32® Solutions

We are a certified SCHOTT partner with ISO 9001certified facilities, offering end-to-end services:

-

- In-house expertise in precision cutting, chemical strengthening, and optical polishing.

-

- Global logistics with moisture-controlled packaging and ISO-compliant traceability.

-

- R&D collaboration for prototyping, stress simulation, and application-specific testing.

Contact Us Request samples, technical datasheets, or a consultation to explore how SCHOTT AF32® Glass can elevate your product’s performance, durability, and design flexibility.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.