SCHOTT D263T

SCHOTT D263T glass is a high-performance, low-iron optical glass produced by SCHOTT GMBH in Germany and widely used in high-precision optical components, medical devices and consumer electronics. It has excellent optical transparency, low iron content and high mechanical strength, and is particularly suitable for the production of lenses, filters, optical glass and other components. The low coefficient of thermal expansion of D263T glass makes it more stable in environments with large temperature variations, while its good workability also makes it ideal for the customization of complex shapes, making it an ideal material for many high-precision optical applications.

-

Ultra-thin and lightweight: With extremely thin thicknesses (from 0.03mm to 1.1mm), suitable for lightweight designs.

-

Excellent optical transparency: Provides high transmittance in the visible, ultraviolet and infrared spectra for optical coatings and sensor protection.

-

High chemical stability: corrosion resistance, moisture penetration resistance, to ensure long-term stability in use.

-

Low coefficient of thermal expansion: good thermal stability, able to resist the stress caused by temperature changes.

Hyperfine surface: Produced using -

SCHOTT’s unique stretching method, the surface is smooth and low roughness, usually less than 1nm, suitable for precision optical applications.

D263®Teco Thin Glass:

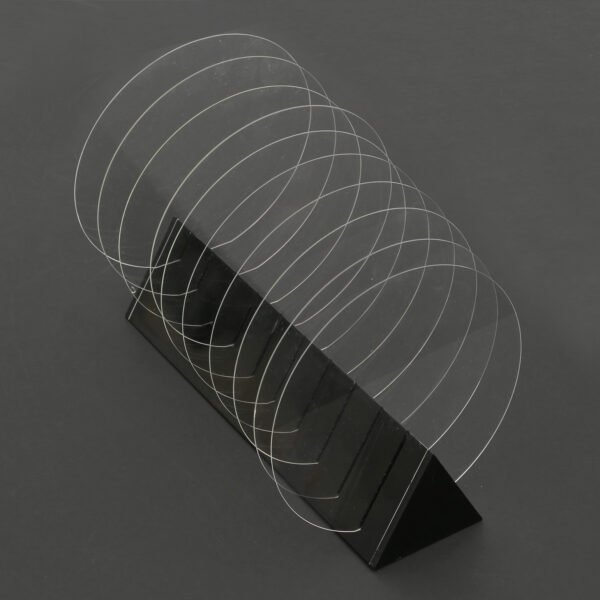

D263®Teco is a pure borosilicate glass with high chemical resistance. It is manufactured by SCHOTT’s special down-draw process and its thickness ranges from 0.03mm – 1.1mm.

D263®Teco borosilicate glass is available in standard sheet sizes, or can be customized to cut into round or square shapes. The product can be used as a substrate for coated glass or to replace plastics used in applications in the automotive and electronics industries.

D263®Teco is manufactured using environmentally friendly refining agents instead of arsenic and antimony.

Product Application:

1. Basic glass in infrared thin film filters

2. Glass element inside the DVD player

3. Touch screen of navigation equipment

4. Caps for laser diodes

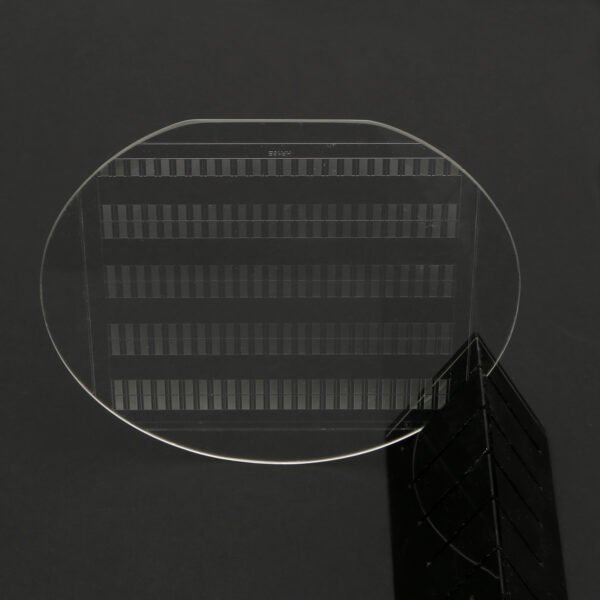

5. Wafer level chip packaging

Product Performance/Features:

1. High resistance to chemical corrosion

2. High light transmittance

3. Smooth fire polished surface

4. Close to the thermal expansion coefficient of ceramics

5. Basic ion mobility

6. High stability to the sun

7. Excellent flexibility

Technical Parameters:

| Thickness (mm) 0.21,0.3,0.4,0.55,0.7 |

| Size 440*360mm, other size according to demand |

| Surface roughness <1 nm RMS |

| VD65 transmittance (d = 1.1mm) 91.7% |

| Coefficient of linear thermal expansion α (20°C; 300°C)(static measurement) 7.2 & sdot;10-6K-1 |

| Conversion temperature 557°C |

| Dielectric constant & epsilon;r at 1 MHz 6.7 |

| Refractive index 1.5230 |

| Density p (calcined at 40 ° per hour) 2.51 g/cm3 |

SCHOTT D 263 applications:

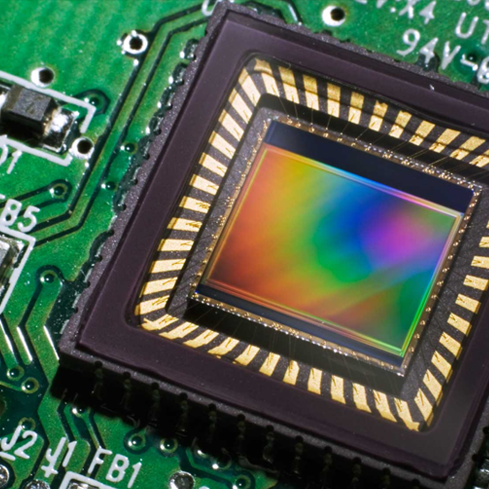

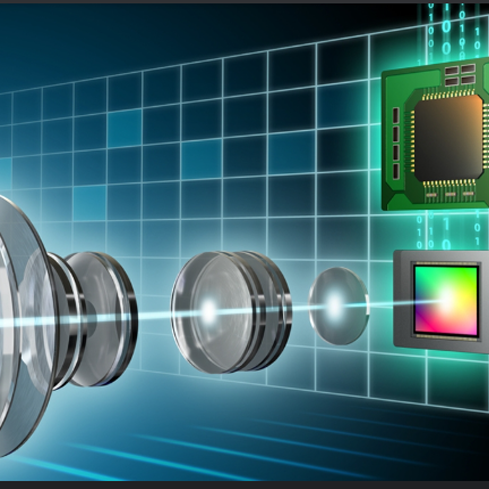

CMOS sensors applications

3D Imaging applications

Semiconductors applications

In the field of high-precision glass processing, SCHOTT D263T glass is ideal for a variety of high-tech applications due to its excellent performance. As an ultra-thin, ultra-clear aluminosilicate glass, D263T has extremely high optical transparency and excellent chemical stability, making it ideal for optically coated substrates such as anti-reflective films and infrared cutting filters.

Our company, LIGHING GLASS, understands the demanding demands placed on glass materials in modern, high-end devices, especially when it comes to protecting display devices, optical components and sensors. With its low coefficient of thermal expansion and excellent thermal stability, SCHOTT D263T glass perfectly meets these needs. Its thin characteristics make it not only have superior resistance to chemical corrosion, but also effectively resist the penetration of moisture, which greatly improves the long-term performance of optical devices and sensors.

We offer SCHOTT D263T glass in a variety of thickness options from 0.03mm to 1.1mm, and can be customized to meet customer requirements. Whether it’s optical coating, precision cutting, polishing, or complex CNC machining, we have a one-stop solution for you. Our services include, but are not limited to:

Optical coating: Single-sided or double-sided anti-reflective coating is available to improve visible light transmission rate.

Infrared cutting filters: Provide accurate IR spectrum control for sensors, cameras and other devices.

Anti-oil coating: improves the cleanliness of the glass surface and prevents the accumulation of fingerprints and stains.

Precision cutting: Cut to the required size according to customer requirements, ensuring that each part meets the requirements of high precision.

In addition, our company is produced and processed in a clean room environment, ensuring that every piece of glass meets the most stringent quality standards. Whether you need GLASS components for AR/VR devices, lightweight displays, or biomedical applications, LIGHING GLASS can provide you with tailored, high-performance solutions to ensure your products remain competitive in the market.

Choose LIGHING GLASS, choose superior quality and precise processing services, let us help you stand out in the fierce market competition.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.