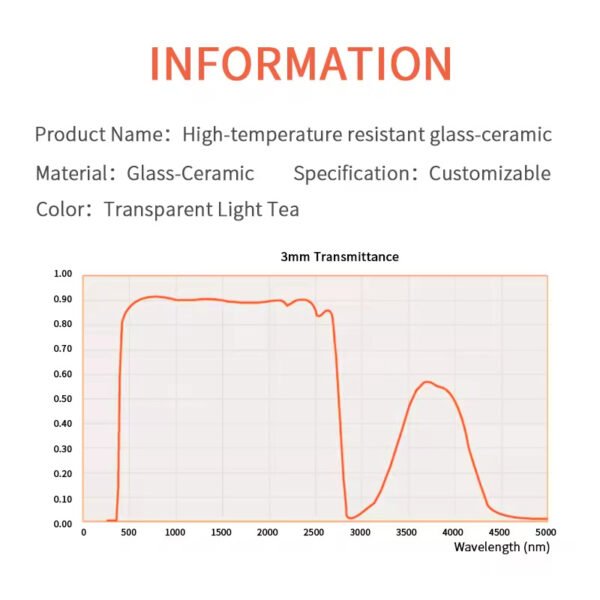

Schott Robax® Glass

As a leading global manufacturer of specialty glass materials, Schott’s ROBAX series glass-ceramic has become a core component of many critical high-temperature systems. Whether for fireplace viewing panels, industrial furnace windows, or specialized optical equipment, this remarkable material has won unanimous praise from the industry with its outstanding thermal properties and unique advantages.

-

Extreme Temperature Resistance: ROBAX operates continuously at temperatures up to 760°C (1400°F) without degradation, making it ideal for the most demanding thermal environments where conventional glass would fail.

-

Zero Thermal Expansion: With a coefficient of thermal expansion near zero (0±0.15 × 10⁻⁶/K), the glass-ceramic maintains dimensional stability even under extreme temperature fluctuations, preventing stress-related failures.

-

Exceptional Thermal Shock Resistance: ROBAX withstands temperature differentials exceeding 500°C, allowing rapid heating and cooling cycles without cracking or structural damage.

-

Superior Optical Clarity: The material maintains over 85% visible light transmission even at high temperatures, ensuring clear visibility in viewing applications while retaining its transparency throughout its service life.

-

Outstanding Chemical Inertness: ROBAX demonstrates excellent resistance to acids, alkalis, and aggressive chemicals, making it suitable for corrosive environments and extending product lifespan significantly.

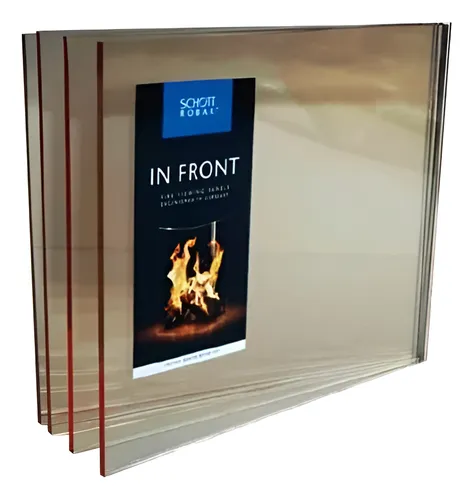

What Is Schott Robax® Glass?

Schott Robax glass is a premium transparent glass-ceramic material specifically engineered for high-temperature applications and extreme thermal environments. This ultra-durable, thermally resistant glass offers exceptional optical clarity and outstanding thermal shock resistance, making it the preferred choice for fireplace doors, oven windows, industrial furnaces, and demanding high-temperature optical applications.

Compared with conventional tempered glass, Schott Robax delivers superior heat resistance, enhanced thermal shock performance, and better long-term stability at extreme temperatures, enabling manufacturers to achieve higher safety standards and superior product durability.

Key Properties of Schott Robax® Glass

- Extreme Heat Resistance: Continuous operating temperature up to 760°C (1400°F)

- Zero Thermal Expansion: Near-zero coefficient of thermal expansion (0±0.15 × 10⁻⁶/K)

- Exceptional Thermal Shock Resistance: Withstands temperature differentials >500°C

- Superior Optical Clarity: >85% light transmission in visible spectrum

- Chemical Inertness: Outstanding resistance to acids, alkalis, and aggressive chemicals

- Dimensional Stability: Maintains precise tolerances under extreme thermal cycling

Applications

- Fireplace and stove viewing panels

- Industrial furnace sight glasses

- High-temperature lab equipment

- Gas oven viewing windows

- Protective covers in high-heat environments

Processing Sizes

Thickness: 3 mm, 4 mm, 5 mm (custom thickness available on request)

FAQ

1. What temperature can SCHOTT ROBAX® Glass withstand?

Up to 800 °C continuously, with short-term peaks of around 1,000 °C.

2. Can ROBAX® Glass be cut to custom sizes?

Yes, it can be cut and shaped to meet specific size requirements.

3. Is ROBAX® Glass suitable for gas fireplaces?

Yes, it’s ideal for both wood-burning and gas fireplaces.

4. How does ROBAX® compare to regular tempered glass?

ROBAX® offers far higher heat resistance and thermal shock durability than tempered glass.

Customize Your Optical Glass Requirements or Inquire About Tailored Solutions

During the checkout process on our website, you can choose custom cutting and laser marking services for your optical glass.

If your needs are more complex, we encourage you to contact our sales engineers through this form to discuss your requirements in detail. During the conversation, we will focus on the following key questions:

- Can we help you achieve your design goals in a more cost-effective way?

- Will your solution perform optimally in the application environment?

- How can we leverage our technical expertise to enhance your design and product?

- Is this design suitable for manufacturing and mass production?

As a professional provider in the optical glass field, we offer custom design and manufacturing services to engineers and technical teams, ensuring each project meets strict performance and quality standards.

Let us apply our experience and expertise to your new or existing projects to help you achieve the best results.