Thermal expansion is an inherent property of all materials—when temperature increases, the size of a material (length, area, or volume) also increases. For glass, which is widely used across multiple high-tech industries, thermal expansion characteristics are critical. From semiconductor packaging and MEMS devices to precision optical systems, the thermal expansion behavior of glass directly influences product reliability and long-term stability.

This article explores the thermal expansion of glass, explains its coefficient of thermal expansion (CTE), and compares different glass types (such as borosilicate and fused silica). We will also discuss how these properties affect key industrial and scientific applications.

What Is Thermal Expansion of Glass?

Simply put, thermal expansion is the phenomenon where materials change dimensions due to temperature variation. When glass is heated, the average kinetic energy of its atoms increases, leading to greater atomic spacing and macroscopic volume expansion.

The coefficient of thermal expansion (CTE, often denoted as α) quantifies this property. It is defined as the fractional change in length or volume per unit temperature change. CTE is typically expressed in units of 10⁻⁶ /K or ppm/K.

- High CTE glass: Expands more when heated and contracts more when cooled.

- Low CTE glass: Shows minimal dimensional change with temperature, offering superior thermal stability.

How Is Thermal Expansion Measured?

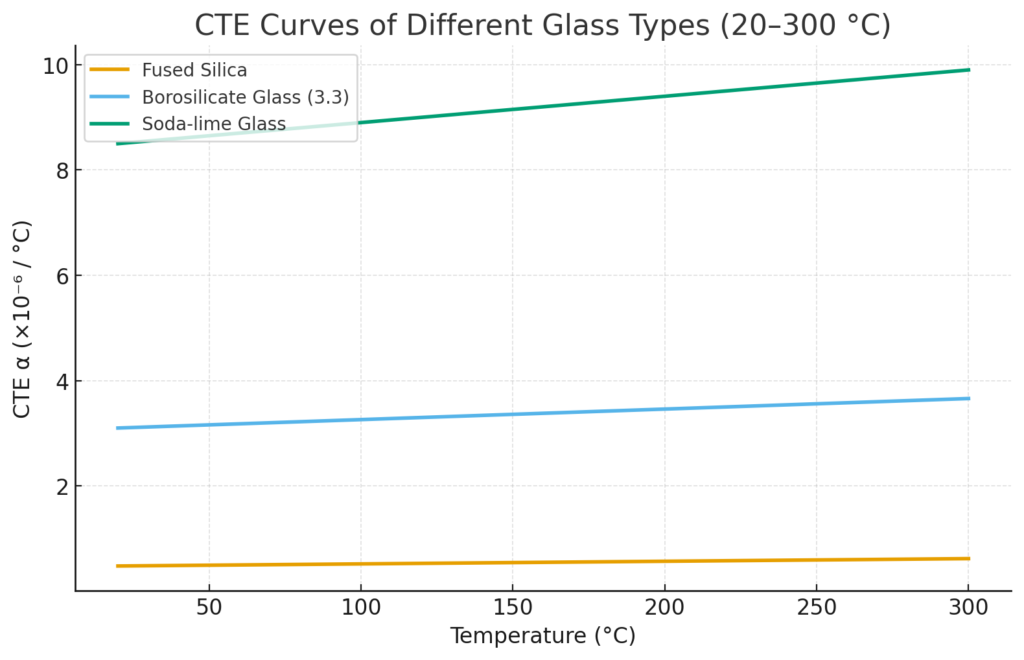

Glass thermal expansion is commonly measured using a Thermomechanical Analyzer (TMA). This instrument records the dimensional changes of a sample under controlled temperature variation. Standardized measurements are usually taken between 20°C and 300°C, yielding an average CTE value for that temperature range.

Coefficient of Thermal Expansion of Different Glass Types

Different glass compositions exhibit significantly different CTE values. Understanding these differences is crucial for selecting the right material.

Borosilicate Glass (e.g., Borofloat® 33, Pyrex®)

- CTE: ~3.25×10⁻⁶ /K

- Features: Low expansion provides excellent thermal shock resistance. Glassware made of borosilicate can withstand rapid temperature changes with minimal internal stress.

- Applications: Laboratory glassware, cooktops, lighting covers, and substrates for semiconductor and industrial uses requiring thermal stability.

Fused Silica (Quartz Glass)

- CTE: ~0.55×10⁻⁶ /K

- Features: Extremely low expansion, close to zero, offering unmatched thermal stability.

- Applications: High-power laser optics, photomask substrates, astronomical mirrors, and precision scientific instruments.

Soda-Lime Glass

- CTE: ~9.0×10⁻⁶ /K

- Features: Relatively high expansion; prone to cracking under rapid heating/cooling.

- Applications: Windows, bottles, containers, and display covers.

Quick Comparison Table: Glass Types and CTE

| Glass Type | Main Composition | Typical CTE (10⁻⁶ /K) | Typical Applications |

|---|---|---|---|

| Fused Silica | High-purity SiO₂ | 0.55 | Lasers, photomasks, astronomy optics |

| Borosilicate | SiO₂, B₂O₃ | 3.25 | Labware, substrates, lighting covers |

| Soda-Lime | SiO₂, Na₂O, CaO | 9.0 | Windows, bottles, containers |

Factors Influencing Thermal Expansion of Glass

Glass Composition and Additives

The chemical composition of glass is the primary factor determining its CTE. For example:

- Boron oxide (B₂O₃): lowers CTE.

- Sodium oxide (Na₂O): significantly increases CTE.

- Lead oxide (PbO): increases CTE, while also raising refractive index.

Optical glass manufacturers carefully control formulations to produce materials with specific CTE and optical performance.

Temperature Range

The CTE of glass is not constant and varies with temperature. Near the glass transition temperature (Tg)—the point where glass shifts from a rigid solid to a viscous state—CTE rises sharply. Therefore, when evaluating thermal expansion, it is important to specify the applicable temperature range.

Impact of Thermal Expansion on Glass Applications

The thermal expansion properties of glass are central considerations in the design of many high-tech products.

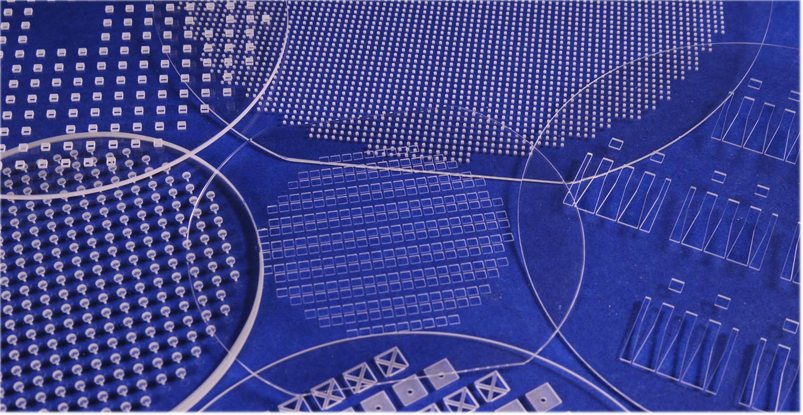

Thermal Expansion Mismatch in Semiconductor and MEMS Packaging

In semiconductor and MEMS (Micro-Electro-Mechanical Systems) packaging, glass wafers or substrates are often bonded or used as support layers. These glasses must match the thermal expansion of silicon.

- Silicon CTE: ~2.6×10⁻⁶ /K

- Thermal expansion mismatch: If the glass substrate and silicon chip have significantly different CTE values, thermal cycling (such as heating during operation) can cause stress. This stress may lead to package cracking, bonding failure, or compromised microstructures.

- Solution: Choose glasses with CTE values close to silicon, such as certain borosilicate glasses or glass-ceramics, to minimize mismatch.

Thermal Shock Resistance of Borosilicate Glass

The low CTE of borosilicate glass makes it ideal for environments with thermal shock. For example, heating a beaker in the lab or using glass bakeware on a stovetop—despite large temperature differences, borosilicate glass maintains its integrity due to minimal internal stress.

Low-Expansion Optical Glass in Precision Optics

In telescope mirrors, laser optics, and space applications, even microscopic dimensional changes can degrade optical performance. These fields rely on ultra-low-expansion glass materials such as fused silica, whose extremely low CTE ensures mirror shapes and focal lengths remain stable across wide temperature ranges, producing sharp and distortion-free images.

Thermal Expansion in Optical Fibers

Optical fibers are typically composed of a high-refractive-index core and a lower-index cladding. The CTEs of the core and cladding must be closely matched. Any mismatch under temperature variation creates stress, increases signal loss, and can even lead to fiber breakage—critical in long-distance communication.

How to Select the Right Glass for Thermal Applications

When choosing the right glass, first define your application’s thermal stability requirements:

- Operating temperature range: Will the product face rapid or wide temperature changes?

- Compatibility with other materials: Will the glass bond with silicon, metals, or ceramics? Matching CTE is essential.

- Balance of performance and cost: Fused silica offers the best performance but at higher cost, while borosilicate provides an excellent balance.

Our expert team can help you select and customize the right glass wafers and substrates to ensure superior performance and reliability in thermal environments.

FAQs

Q: Is a higher or lower CTE better?

A: Neither is inherently better. It depends on the application. Low-CTE glass is ideal for resisting thermal shock or bonding with low-expansion materials. In other cases, higher CTE glass may be necessary to match high-expansion materials.

Q: Why does glass thermal expansion matter in semiconductor packaging?

A: Semiconductor chips generate heat during operation. If the CTE of packaging glass differs from that of silicon, different expansion rates during heating will create thermal stress, potentially leading to cracks or failures.

Q: What’s the difference between borosilicate glass and fused silica?

A: Fused silica is made of high-purity SiO₂, has an ultra-low CTE (~0.55×10⁻⁶ /K), and provides extreme stability, but is expensive. Borosilicate contains B₂O₃, has a higher CTE (~3.25×10⁻⁶ /K), but still much lower than ordinary glass, making it more cost-effective.

Q: Does the CTE of glass change with temperature?

A: Yes. CTE is not constant. At low temperatures, variation is modest, but near the glass transition temperature (Tg), CTE increases significantly. That’s why specifications always include the temperature range.FAQs

Q: Is a higher or lower CTE better?

A: Neither is inherently better. It depends on the application. Low-CTE glass is ideal for resisting thermal shock or bonding with low-expansion materials. In other cases, higher CTE glass may be necessary to match high-expansion materials.

Q: Why does glass thermal expansion matter in semiconductor packaging?

A: Semiconductor chips generate heat during operation. If the CTE of packaging glass differs from that of silicon, different expansion rates during heating will create thermal stress, potentially leading to cracks or failures.

Q: What’s the difference between borosilicate glass and fused silica?

A: Fused silica is made of high-purity SiO₂, has an ultra-low CTE (~0.55×10⁻⁶ /K), and provides extreme stability, but is expensive. Borosilicate contains B₂O₃, has a higher CTE (~3.25×10⁻⁶ /K), but still much lower than ordinary glass, making it more cost-effective.

Q: Does the CTE of glass change with temperature?

A: Yes. CTE is not constant. At low temperatures, variation is modest, but near the glass transition temperature (Tg), CTE increases significantly. That’s why specifications always include the temperature range.

Contact our expert team today for customized glass solutions